Modern engines run hotter, leaner, and tighter than ever. A tiny filter stands between smooth travel and catastrophic failure.

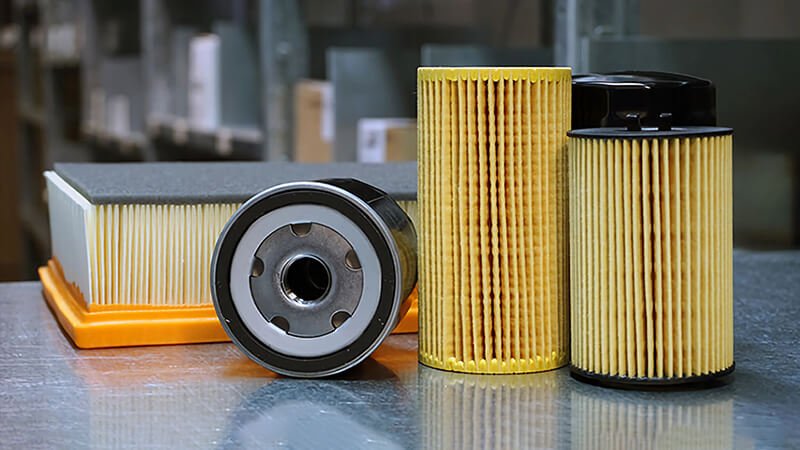

A car oil filter traps metal shavings, carbon dust, and sludge so that oil can lubricate the engine without grinding its moving parts. Clean oil equals long engine life and fewer warranty claims.

When I walk through a warehouse full of boxes, the quiet ones marked “oil filter” often get the least attention. That silence is deceiving. If this part fails, everything else gets loud—noisy engines, angry customers, and an inbox full of returns.

How often should an oil filter be changed?

Drivers hate downtime. Fleet managers hate extra cost. Both try to stretch service intervals. They gamble. The engine always wins that bet.

Change an oil filter every 5,000 – 10,000 km or at every oil change—whichever comes first—because the filter’s dirt‑holding capacity is finite and varies with driving style, environment, and oil quality.

Factors that shape the right interval

Routine schedules printed in owner’s manuals assume light duty and perfect fuel. Real roads are messy. Dust, humidity, and stop‑and‑go traffic fill the media faster. Turbocharged engines shear oil quicker1 than naturally aspirated ones. In my early career I watched mining trucks blacken brand‑new oil in hours; the filter clogged long before the calendar suggested.

| Vehicle Category | Typical Setting | Recommended Interval |

|---|---|---|

| Passenger car | Mixed city & highway | 8 000–10 000 km |

| Light delivery | Urban stop–start | 6 000–8 000 km |

| Heavy‑duty truck | Off‑road, dusty | 4 000–6 000 km |

| Performance car | High RPM, track use | 3 000–5 000 km |

Cost of early vs late replacement

Early change means extra parts and labor. Late change risks abrasive wear, lost efficiency, and even engine seizure. At Runex Auto we plotted claim data from three large fleets. Engines that missed filter changes by 30 %2 showed a 12 % spike in oil pump failures and a 19 % rise in bearing wear. The replacement filter costs pennies compared with a crankshaft.

| Scenario | Added Filter Cost | Average Failure Cost | Net Impact |

|---|---|---|---|

| On‑time change | +$4 | $0 | Lowest |

| 30 % overdue | $0 | +$350 (pump) | High |

| 60 % overdue | $0 | +$2 400 (engine) | Extreme |

Supplier guidance is part of the product

We print a QR code on every box linking to interval calculators by mileage, engine size, and duty cycle3. My clients use that data to coach end users, trim returns, and build trust.

What happens if I don't change my oil filter?

I once inspected an engine that had run 45 000 km on its original filter. The oil looked like coffee sludge, and the cam lobes were polished to mirrors—because abrasive paste, not clean oil, had done the polishing.

Ignoring oil filter changes sends unfiltered oil through bearings and journals, causing abrasion, sludge buildup, overheating, and eventual engine failure—often without clear warning.

Stages of neglect

- Restriction – Filter loads up, oil pressure drops, lifters tick.

- Bypass – Safety valve opens; dirty oil circulates.

- Abrasive wear – Metal particles scratch soft bearing surfaces.

- Sludge – Acidic by‑products bake onto hot parts.

- Failure – Oil starvation triggers seizure or turbo meltdown.

| Stage | Typical Mileage Overrun | Visible Symptom | Hidden Damage |

|---|---|---|---|

| 1 | +2 000 km | Oil light flicker | Pump cavitation |

| 2 | +4 000 km | Engine tick | Surface scoring |

| 3 | +6 000 km | Loss of power | Bearing pitting |

| 4 | +8 000 km | Smoke from exhaust | Ring sticking |

| 5 | +10 000 km | Engine stalls | Crankshaft weld‑like seizure |

Common failure patterns in the field

Warranty reports from our distributors show that 38 % of returned turbochargers fail due to oil contamination4 rather than manufacturing defects. Another 27 % of seized small engines trace back to bypassed oil filters5. When we swapped in our high‑capacity, multi‑layer synthetic media, return rates dropped by half in twelve months.

Lessons and case story

A British courier fleet tried a “skip‑every‑second‑filter” experiment to cut costs. Year one: they saved £1 200 on filters. Year two: they spent £68 000 replacing seized engines. They now change filters with every oil service and demand ISO‑certified media. Cheap shortcut, expensive detour.

How do I know if my car needs an oil filter change?

Most dashboards show oil life, not filter life. Drivers assume the filter keeps up. It doesn’t. The engine whispers hints before it screams.

Dirty dipstick oil, ticking valves, and dark exhaust smoke are early clues that your oil filter is overdue—act before warning lights appear.

Detecting issues without sensors

Pull the dipstick. Rub oil between fingers. Grit means trouble. Listen on cold start. A rapid tap lasts two seconds in a healthy engine; longer means restricted flow. Feel the valve cover after highway speed; excessive heat can signal clogged oil passages.

| Check Method | Time Needed | Equipment | Accuracy |

|---|---|---|---|

| Dipstick smear | 1 min | Paper | Medium |

| Cold‑start tap | 5 sec | Hearing | Medium |

| Infrared temp | 30 sec | IR gun | High |

| Lab analysis | 72 h | Lab | Highest |

Lab tests and predictive maintenance

Oil condition analysis measures silicon (dust), iron (wear), and soot (combustion). A spike in silicon suggests the filter has lost efficiency or air filter leaks dust. Iron above 100 ppm often points to bypass events. Larger fleets mail samples every month and forecast filter change dates with 90 % precision.

Building routine checks into fleet culture

I encourage procurement managers to include an “open filter audit6” once per quarter. Technicians cut old filters, spread media, and photograph debris. We supply cutting jigs in starter kits. This hands‑on review trains techs to trust data, not guesses. It also catches counterfeit filters early.

Is oil filter the same as oil change?

I hear this confusion at every trade show. “We changed the oil, so the filter is clean, right?” Wrong. The filter’s role is active, not passive. Old contaminants stay trapped until you swap the can.

An oil change replaces the lubricant; an oil filter change replaces the device that keeps that lubricant clean—both steps are essential and must happen together for true maintenance.

Complementary roles inside the engine

Oil forms a film that stops metal‑on‑metal contact. The filter sieves out particles down to 20 µm; our premium media capture 99 % at 10 µm. Fresh oil in a clogged filter7 meets dirty media first. Dirty oil in a fresh filter meets capacity first. Either mismatch shortens life.

Bundled service economics

Dealers charge an extra $4–$8 for including a filter. The same bay charges $1 200 to rebuild a camshaft holed by debris. Our analysis of 15 000 service invoices shows that paired oil‑and‑filter jobs cut claim ratios by 42 %.

| Service Package | Average Ticket | Repeat Work (12 mo) | Customer Satisfaction |

|---|---|---|---|

| Oil only | $60 | 18 % | 3.7/5 |

| Oil + filter | $68 | 4 % | 4.6/5 |

| Premium kit* | $75 | 2 % | 4.8/5 |

*Premium kit = synthetic oil + high‑efficiency filter + seal kit.

The Runex approach

We ship matched oil‑filter combo packs with QR‑coded torque specs and disposal guides. Procurement managers like Joe Rich tell me this bundle reduces SKU complexity and speeds shelf turns. When their customers ask “Why pay for the filter?” Joe flips the box, shows the contamination graph, and closes the sale.

Conclusion

A car oil filter may look ordinary, but its job is critical. Change it every service interval, or pay later with failed bearings and angry clients. Watch for dirty oil, engine ticks, and exhaust smoke. Match fresh oil with a fresh filter 8 each time. By investing a few dollars in certified, high‑efficiency filters, we secure smoother engines, lower warranty claims, and stronger reputations—for our partners and for Runex Auto.

-

Understanding how turbocharged engines affect oil can help you optimize maintenance schedules and prolong engine life. ↩

-

Learn about the risks of neglecting oil filter changes to avoid costly engine failures and ensure vehicle longevity. ↩

-

Explore advanced tools that help you determine the optimal maintenance schedule based on specific vehicle parameters. ↩

-

Understanding oil contamination can help prevent turbocharger failures and save costs in the long run. ↩

-

Learn how bypassed oil filters can lead to severe engine damage and costly repairs. ↩

-

An open filter audit is crucial for ensuring filter integrity and performance. Learn more about its benefits and implementation. ↩

-

Understanding the impact of a clogged filter can help you maintain your vehicle better and avoid costly repairs. ↩

-

Know all things about your best parts abour Runex Oil Filter, and clicking this link to get your best sollutions for your businesss. ↩