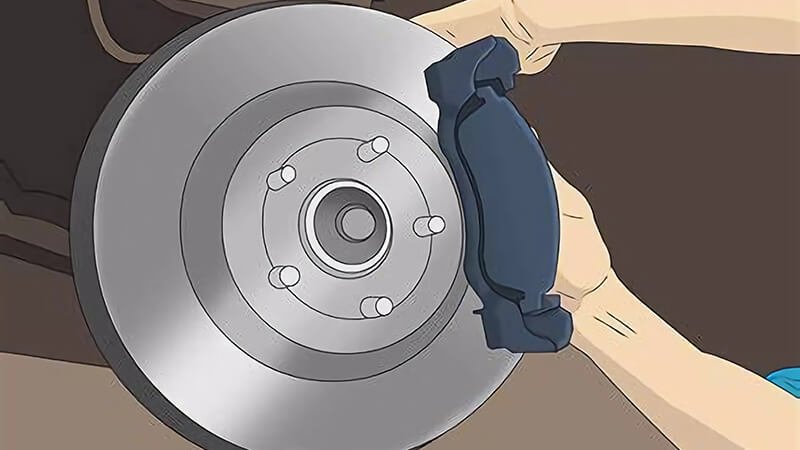

When it comes to ensuring your vehicle’s safety and performance, the quality of your brake pads is crucial. But with so many options available, should you go for American-made brake pads? In this article, we’ll explore why choosing brake pads made in the USA could be the best decision for your car’s needs.

American-made brake pads are often associated with higher quality, reliability, and compliance with strict manufacturing standards. By choosing these pads, vehicle owners can ensure better safety, performance, and durability. But are they really worth the extra investment? Let's dive into the details.

While American-made brake pads are a popular choice, there are many factors to consider when selecting the right option for your vehicle. In the following sections, we'll discuss what makes American-made brake pads stand out and how to determine the best fit for your car.

Which brake pads are made in the USA?

With countless brake pad brands out there, it can be difficult to identify which ones are truly made in the USA. Are you getting what you pay for? Let’s look at some of the leading manufacturers that produce brake pads in the USA and why their products stand out.

Several reputable brands manufacture brake pads in the USA, including well-known companies like Bendix1, AC Delco2, and Wagner3. These manufacturers meet strict American manufacturing standards, ensuring high-quality, reliable brake pads for your vehicle. But how do these brands compare to others?

Brake pads made in the USA come with a sense of trust due to the rigorous standards enforced by American regulations. Leading manufacturers, such as Bendix, AC Delco, and Wagner, ensure that their products are designed with high-quality materials and undergo thorough testing for safety, performance, and durability. These brands are known for their commitment to meeting stringent quality control standards, ensuring that every set of brake pads they produce offers consistent and reliable performance.

American-made brake pads benefit from superior craftsmanship and high manufacturing standards that help ensure safety and reliability. For instance, American manufacturers adhere to Federal Motor Vehicle Safety Standards (FMVSS) set by the National Highway Traffic Safety Administration (NHTSA), which governs the safety of brake pads in the automotive industry. This is a key factor that sets American-made brake pads apart from many international brands, which might not meet these standards.

Additionally, local production allows manufacturers to oversee the quality of every product that rolls off the production line. This reduces the chances of defects that could compromise the safety and performance of the brake pads. It also minimizes the risk of subpar materials being used, as American manufacturers tend to source quality materials locally and maintain a close eye on the entire production process. With brake pads being such a critical component of vehicle safety, this attention to detail is crucial.

However, it's essential to note that not all American-made brake pads are created equal. While brands like Bendix and AC Delco are synonymous with quality, other manufacturers might not have the same level of commitment to excellence. Therefore, it’s essential for consumers to research each brand and model before making a purchase to ensure that they’re getting the best value for their money.

| Brand | Manufacturing Location | Quality Standard | Materials Used | Performance Features |

|---|---|---|---|---|

| Bendix | USA | FMVSS Compliance | High-quality metal | Smooth, reliable braking |

| AC Delco | USA | FMVSS Compliance | Ceramic, semi-metallic | Long-lasting, noise-free |

| Wagner | USA | FMVSS Compliance | Organic, semi-metallic | Excellent heat resistance |

Are factory brake pads better than aftermarket?

When it comes to replacing your brake pads, should you go with factory-original equipment (OE) parts or aftermarket options? The decision can be tough, as each option has its own advantages. Let's break down the differences and see which one might be the best choice for you.

Factory brake pads are designed to fit your vehicle perfectly, but aftermarket brake pads offer flexibility and cost savings. While factory pads guarantee a precise fit, aftermarket options can provide improved performance and longer life, depending on your needs. So, which should you choose?

Factory brake pads, also known as original equipment (OE) parts, are designed and manufactured by the car’s manufacturer specifically for that make and model. The benefit of OE brake pads is that they’re guaranteed to fit your vehicle and perform as expected. They have undergone extensive testing to ensure they meet the manufacturer's exact standards for performance, safety, and durability. For many car owners, this reliability is worth the price.

However, factory brake pads often come at a higher cost compared to aftermarket options. In addition, OE pads are generally designed to meet the basic needs of a vehicle, which may not provide the best performance for specific driving conditions, such as heavy towing or aggressive driving.

On the other hand, aftermarket brake pads offer a wider range of options that can be tailored to your driving style and needs. These pads are manufactured by third-party companies and can provide various features that factory brake pads may lack, such as better heat dissipation, longer life, and superior stopping power. Aftermarket brake pads come in a variety of materials, such as ceramic4, semi-metallic5, and organic6, each offering distinct benefits depending on your driving habits.

For example, if you live in an area with frequent rain or snow, you may want to consider ceramic brake pads, as they provide better performance in wet conditions and produce less dust. On the other hand, if you do a lot of towing or drive in mountainous terrain, semi-metallic brake pads might offer better stopping power under heavy loads.

| Brake Pad Type | Advantages | Disadvantages | Best for |

|---|---|---|---|

| Factory (OE) | Guaranteed fit, brand consistency | Higher cost, limited customization | Standard driving conditions |

| Aftermarket | Customizable, better performance options | Varying quality, less reliable for some | Performance, special needs |

The downside of aftermarket brake pads is that they can vary greatly in quality. While many aftermarket brands offer excellent products, there are also subpar options that might not perform as well as factory pads. This can make it difficult for consumers to make an informed decision. Thus, when choosing aftermarket brake pads, it’s important to consider the reputation of the manufacturer and read customer reviews to ensure you’re selecting a high-quality product.

Does the brand of the brake pad matter?

With so many brands available, does the name on the box really matter? Is it worth paying more for a premium brand, or can a budget-friendly option do just as well? Let’s take a look at why the brand of brake pads might have a significant impact on their performance and durability.

Yes, the brand of brake pad does matter. Established brands tend to offer higher quality products that undergo rigorous testing to ensure optimal performance and safety. While cheaper options may seem tempting, they can come with trade-offs in performance, safety, and longevity.

The brand of brake pads you choose plays a crucial role in the overall performance, safety, and lifespan of the parts. Established brands such as Bendix7, AC Delco8, and Wagner9 are known for their consistent quality and reliability. These companies invest significant resources into research, development, and testing to ensure their brake pads deliver exceptional performance in various conditions.

Choosing a well-known brand offers peace of mind, knowing that the brake pads have undergone rigorous testing to meet safety standards and will deliver consistent performance over time. These brands use high-quality materials and maintain strict quality control measures to ensure that each brake pad is up to par with industry standards. Their products are often backed by warranties, further assuring customers of their durability and reliability.

On the other hand, opting for budget-friendly or lesser-known brands can be a gamble. While these brake pads may offer a lower upfront cost, they can sometimes fall short in terms of performance and longevity. Inferior materials may lead to faster wear, noisier operation, and less efficient braking. Additionally, these cheaper options may not adhere to the same safety standards as established brands, potentially compromising your vehicle's braking performance.

| Brand | Testing Standards | Material Quality | Warranty Offered | Reliability |

|---|---|---|---|---|

| Bendix | Extensive R&D, FMVSS tests | Premium materials | 1-year warranty | Very reliable |

| AC Delco | FMVSS Compliance | Ceramic, semi-metallic | 1-2 years warranty | Reliable |

| Wagner | Strict quality checks | Organic, semi-metallic | 1-year warranty | Reliable |

| Budget Brands | Varies, limited tests | Low-quality materials | Limited or none | Unreliable |

In the end, the brand of brake pads does matter, especially when it comes to your safety and the safety of others on the road. While it’s tempting to save a few dollars, investing in a reputable brand could save you money in the long run by reducing the need for frequent replacements and avoiding potential safety hazards.

What type of brake pads are the best?

When it comes to selecting the best brake pads for your vehicle, the type of material and the performance requirements should be at the forefront of your decision. But which type of brake pads is best suited for your needs? Let's dive into the options.

The best type of brake pad depends on your driving conditions. Ceramic10, semi-metallic11, and organic12 brake pads each offer distinct advantages. Whether you need superior performance in extreme conditions or quieter, dust-free operation, the right choice will enhance your vehicle’s braking power.

There are three main types of brake pads to choose from: ceramic, semi-metallic, and organic. Each has its own unique benefits and drawbacks, so selecting the right one depends on your specific needs and driving conditions.

-

Ceramic brake pads are made from a mixture of ceramic fibers and other materials. They are known for their quiet operation and low dust production, making them a great choice for drivers looking for a clean and smooth ride. Ceramic pads also offer good heat resistance and last longer than organic pads. However, they tend to be more expensive than other types, making them a higher investment.

-

Semi-metallic brake pads are made from a blend of metal materials, such as steel and copper, along with other components. These pads offer superior stopping power and performance under high temperatures, making them ideal for drivers who often tow heavy loads or drive in mountainous areas. However, they can be noisier and produce more brake dust compared to ceramic pads. Semi-metallic pads are also harsher on the rotors, which can lead to faster wear and tear.

-

Organic brake pads are made from non-metallic materials, such as rubber, carbon, and Kevlar. They are generally the quietest option and produce the least brake dust. Organic pads are typically less expensive, but they wear out faster and may not perform as well in high-temperature conditions compared to ceramic or semi-metallic pads.

The best type of brake pad for your vehicle will depend on your driving style and needs. If you primarily drive in urban environments with minimal heavy braking, ceramic pads may be the best choice for their quiet performance and longevity. For those who drive in more demanding conditions or tow heavy loads, semi-metallic pads may offer the best performance. Finally, organic pads may be ideal for those on a budget or looking for a quieter, low-dust option for lighter driving.

| Brake Pad Type | Materials Used | Advantages | Disadvantages | Best for |

|---|---|---|---|---|

| Ceramic | Ceramic fibers, copper | Quiet, low dust, long-lasting | Higher cost, not ideal for extreme heat | Urban driving, light driving |

| Semi-metallic | Steel, copper, graphite | Superior stopping power, better heat resistance | Noisier, more brake dust, harsher on rotors | Towing, mountainous terrain, heavy-duty use |

| Organic | Rubber, carbon, Kevlar | Quiet, low dust, low cost | Shorter lifespan, less heat resistance | Budget-conscious, city driving |

Conclusion

Choosing the right brake pads for your vehicle is essential for maintaining safety, performance, and longevity. While American-made brake pads offer significant advantages in quality and reliability, it's also important to consider the type and brand of brake pads that best suit your needs. Whether you choose factory or aftermarket, premium or budget-friendly, selecting the right brake pad type can improve your vehicle’s performance on the road.

-

Learn how Bendix, AC Delco, and Wagner adhere to US manufacturing standards for high-quality brake pads. ↩

-

Understand how FMVSS and NHTSA ensure brake pad safety and quality in the USA. ↩

-

Explore quality control and production processes for American-made brake pads. ↩

-

Learn how ceramic brake pads perform better in wet conditions and produce less dust. ↩

-

Discover why semi-metallic brake pads are ideal for heavy towing and aggressive driving. ↩

-

Compare the benefits of organic, ceramic, and semi-metallic brake pads for different driving styles. ↩

-

Learn how Bendix ensures high-quality brake pads with reliable performance and long-lasting durability. ↩

-

Discover how AC Delco invests in research and testing to guarantee the safety and reliability of its brake pads. ↩

-

Find out how Wagner brake pads meet industry standards and maintain quality control for optimal braking performance. ↩

-

Learn about the advantages of ceramic brake pads, including quiet operation and longer lifespan. ↩

-

Discover how semi-metallic brake pads offer superior stopping power and high-temperature performance. ↩

-

Understand the benefits and limitations of organic brake pads, including cost and performance in various conditions. ↩