I see buyers ask this every quarter. The choice looks simple. It is not. Cost, service time, waste, and warranty all sit behind it. I use a clear view. I start with how your fleet works. I end with how your budget and brand need to grow.

The better choice depends on your goals. Spin-on filters are fast to install and common across the UK and Europe. Cartridge filters cut waste and lower long-term cost. At Runex Auto, I offer both. I match flow, micron, and media to your engine spec. I also match your logistics plan.

I want you to stay with me for the details. I show how each design works in the real world. I share test data and stories from UK distributors. I keep the language simple. I show where money goes. I also show how you can lower risk in peak months.

Which is better spun filter or thread filter?

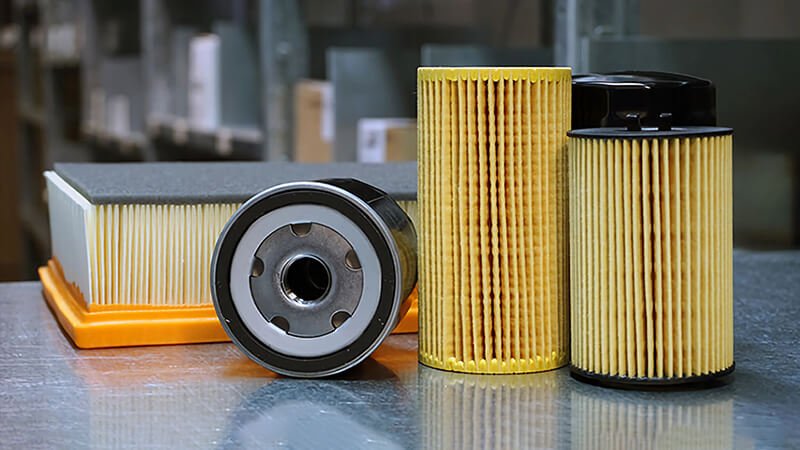

You may call a spin-on filter a spun or threaded filter. Many do. It feels simple to use. You screw it on. You take it off. It comes as one unit. It looks strong. It also looks safe under heat and pressure.

The spin-on filter is better when you want speed and less training. The cartridge filter is better when you want low waste, easy inspection, and lower long-term cost. At Runex Auto, I build both to OE spec. I choose silicone valves for heat. I use high-efficiency media for soot and sludge. I test bypass opening, burst pressure, and flow under cold start.

How spin-on and cartridge compare in the bay

I keep the view simple. A spin-on filter1 is a sealed can. You replace the full can at each service. A cartridge filter2 is a bare element. You keep the housing. You replace the element and O-rings. Now I go deeper.

-

Design and service

- Spin-on units need no housing. They need a clean seat and a good hand torque. They use a baseplate, a can, a bypass valve, and an anti-drainback valve. In my line, I use rolled seams and laser-checked weld circles. I set bypass around 1.0–1.2 bar for common European petrol engines, and 1.5–2.0 bar for many diesel units. I use silicone anti-drainback for high heat stability.

- Cartridge units sit in an OEM housing. You see the element. You change the O-rings. You torque the cap to spec. You get lower waste since you do not throw the can away. You also see debris on the pleats. So you can catch early wear.

-

Field impact

- Service time: A trained tech changes a spin-on in 2–4 minutes. A cartridge takes 3–6 minutes due to cap torque and O-rings. After 2–3 services, times are similar.

- Waste: A spin-on is up to 70–80% metal by weight. A cartridge is near 90% media and polymer, with a small plastic frame. Waste fees drop with cartridges in many EU zones.

- Leaks and comebacks: Spin-on leaks often come from double-gasket events. Cartridge leaks often come from wrong cap torque or old O-rings. I include torque notes and O-ring grease tips in each Runex Auto box insert.

-

Cost and TCO

- Unit price: Spin-on can be cheaper each piece in older platforms. Cartridge is cheaper in many new platforms because you reuse the housing.

- TCO: Cartridge wins where waste disposal3 and freight cost are high. Spin-on wins where labor time and training matter most, like pop-up service bays.

Here is a quick view of specs I ship most for both types.

| Attribute | Runex Spin-on (example) | Runex Cartridge (example) |

|---|---|---|

| Efficiency @ 20 μm | >= 99% (Beta 200) | >= 99% (Beta 200) |

| Bypass valve | 1.2–1.6 bar | 1.2–1.6 bar (in housing) |

| Anti-drainback | Silicone -40 to 200 C | In housing or not needed |

| Burst pressure | > 20 bar | N/A (housing rated) |

| Media | Synthetic blend | Synthetic blend |

| Max service interval | As per OEM | As per OEM |

I do not claim one is best for all. I match platform, climate, oil grade, and drain interval. I also match your stocking plan. I keep drop-in cross references for UK and EU fleets. I can preload mixed pallets with both types when you face a mixed park.

What is the best oil filter to use?

The best filter is the one that meets the engine spec, holds dirt to the drain, and protects during cold starts and high load. It must also fit your service model and your warehouse plan. I design to OE or above. I pick media and valves by platform, not by gut.

The best filter uses stable media, reliable valves, and a tight seal. It meets ISO 4548-12 or ISO 16889 data. It holds the right grams of contaminant. It reaches the right beta ratio. It also ships on time. I test, I certify, and I track lots. Runex Auto delivers this as standard.

The real criteria I use to choose “best”

I keep this simple and strict. I rate a filter by what it does in the engine, in the lab, and in your warehouse.

-

- Micron rating alone can mislead. I use beta ratios. Beta 200 at 20 microns means 99.5% capture at that size. That matters for modern turbo petrol and diesel engines. Soot and varnish need stable capture across a wide size range.

- Media choice: I use synthetic or synthetic blend media for long drains. Cellulose can be enough for short drains. Synthetic handles heat and water better. It holds shape under pressure pulses. It resists collapse.

-

- Cold start: Oil is thick in winter. I size the media area and set the bypass to avoid starvation. I test at -20 C flow and rapid rise to 5 bar. I verify the anti-drainback valve keeps the gallery wet after shutoff.

- High load: I test at 120 C oil and surge flow. I check collapse and pleat stability. I choose a steel core with spiral center tubes in spin-ons. I choose rigid cages in cartridges.

-

- Gaskets: I use NBR for standard and switch to silicone for high heat or long intervals. I test compression set after 24 hours at 150 C.

- End caps: I avoid weak glues. I run thermal shock cycles. I check media potting for voids by X-ray spot checks on new runs.

-

- I ship with lot codes and barcodes. I keep PPAP files for OEM customers. I keep material certs. I can share ISO test curves when you need a tender.

-

- Packaging: I use stackable cartons that resist crush. I print torque and oiling tips. I add O-ring lube notes for cartridges. This lowers comebacks and helps new techs.

- Supply: I keep UK and EU hub stock for the top 80% movers. I plan container splits to avoid peak season gaps.

Here is a short table that shows how I choose the best filter for a platform.

| Platform need | Spin-on pick | Cartridge pick6 | Why it fits |

|---|---|---|---|

| Short service intervals | Cellulose blend, NBR gasket | Cellulose blend, standard cage | Adequate, cost-focused |

| Long drain, high temp | Full synthetic, silicone ADBV | Full synthetic, high-temp O-rings | Stability and clean flow |

| Cold climate | Lower bypass, high flow media | Lower bypass in housing, silicone seals | Quick pressure on start |

| Eco goal, waste limits | Recyclable can program | Cartridge element only | Lower waste fees |

| Tight bay time | Spin-on with knurl, pre-lube gasket | Quick-cap housing, pre-sized O-rings | Faster swaps |

In the UK and Europe, ease of install drives many shops to spin-on. I support that with strong SKUs and clear cross references. But I also see a fast move to cartridges in new models. So I tool both lines. I make sure your team can stock one supplier and cover both types.

Are cartridge filters better?

Cartridge filters are better when you want less waste and lower per-service cost. They also help when you want to inspect the element. They fit green goals and audit checklists. They can be safer to ship because you move less metal. They can cut storage volume per unit.

Cartridge filters are not always better for speed. They can be slower in the first months while techs learn torque steps. They can fail if O-rings are not replaced. My team solves this with clear cap torque guides and bagged O-rings in each box. We add QR videos. This closes the gap fast.

Why I recommend cartridges for many new fleets

I go deep on real use. I do not just repeat a trend. I look at the full chain: bench test, workshop time, and waste bills.

-

Waste and cost

- A cartridge element1 cuts metal waste by up to 80% per service. Many UK and EU councils charge by weight and type. Cartridges lower these bills. They also lower carbon in shipping due to lower weight and smaller boxes.

- Unit price moves with platform. For many Euro 6 and newer engines, the cartridge element is cheaper than an OE spin-on unit. You reuse the housing. You pay for media and seals only.

-

- You can inspect the old element. You can see metal, soot, and sludge. You can catch bearing wear early. You can plan an oil lab test if you see a pattern. This data helps warranty calls.

- You can replace O-rings each time. You reset the seal to new. This reduces slow weeps that cause returns.

-

- I can tune the element height, pleat count, and cage stiffness with more freedom in cartridges. I use glass fiber blends for long drains. I add molded end caps with positive stops to avoid crush. I design keying to stop wrong installs.

-

Risk and training

- Most failures come from cap over-torque or reused O-rings. I add torque on the box flap. I add a bright O-ring packet. I include a torque spec card. I also offer short video clips for new techs. This turns the first month into a smooth path.

Table below shows where cartridges shine.

| Benefit area | Cartridge impact | Detail at Runex Auto |

|---|---|---|

| Waste | -60% to -80% per service | Element only, recyclable cartons |

| Cost per service | Lower over 12–24 months | Media-only replacements, bulk O-rings |

| Quality insight | High | Visual check of pleats and debris |

| Training time | Moderate then low | Box torque guide, QR videos |

| Supply resilience | High | Compact packing, more units per pallet |

A UK distributor I work with had delays in peak season due to spin-on shortages. They held many SKUs with low turns. They switched key lines to cartridges where the platform allowed it. They raised pallet density and reduced per-order weight. They met eco targets and saved on waste fees. They also cut backorders by 38% in Q4. This came from better stocking and faster inbound. The result matched their brand promise, not just a cost line.

Why are manufacturers going to cartridge filters?

Manufacturers move to cartridges because they see the full life cycle. They want lower waste and easy recycling. They want lower shipping weight and smaller packaging. They want better control of fit with the fixed housing. They also want stable supply of a simple element.

They also move for regulations and ESG goals. Many EU rules push for less mixed waste. Cartridges help. Plants also want simpler assembly and better access for service. A cartridge gives that. So the trend is strong in Europe and Asia. I build for this shift.

The drivers behind the cartridge shift

I speak with OEMs and tier-ones. I hear the same list. It is not a fad. It is a design choice tied to cost, regulation, and service.

-

- Less metal waste: Easy sorting and recycling. Lower landfill. Good for ISO 14001 audits.

- Lower transport CO2: Smaller boxes and lighter loads. More units per container. Lower damage rate.

-

Engineering and quality

- Fixed housing: Better control of leak paths. Cap torque sets seal load. Housing integrates bypass in many designs. This reduces part variation in the field.

- Media flexibility: Engineers can iterate the element without changing the engine boss. This helps mid-cycle updates.

-

Service and customer experience2

- Cleaner service: Less oil spillage in top-down housings. Less mess on undertrays. Easier for hybrid layouts with tight engine bays.

- Visible condition: Techs show customers the dirty element. It builds trust. It reduces arguments over service need.

-

- Simpler BOM: One housing, many element suppliers. Easier multisource strategy. Faster ramp across regions.

- Better palletization: Higher cube efficiency. Lower breakage. Easier to keep buffer stock.

Here is a table that lines up the reasons and what I do at Runex Auto to support them.

| Reason OEMs switch | What changes at OEM | How Runex supports |

|---|---|---|

| Lower waste targets | Cartridge element adoption | High-efficiency media, recyclable packs |

| CO2 and logistics | Smaller parts, fewer SKUs | Dense packing, EU hub stocking |

| Service quality | Top-mounted housings | O-ring kits, torque guides |

| Cost and resilience | Multisource elements | Cross-verified tooling, PPAP, lot trace |

| Design updates4 | Mid-cycle media tweaks | Fast revalidation, ISO test reports |

I also hear a common fear. People worry about cap cracks and stripped threads. This is real when cheap housings meet wrong torque. My answer is two-fold. First, I spec O-rings with the right hardness. This lowers torque needed to seal. Second, I print torque, oil level, and cap lube steps on the flap. I make the right way the easy way. This keeps your comebacks low and your ratings high.

Transition to a blended strategy

I do not force one type on you. I use data. In the UK and Europe, spin-on filters still dominate in older fleets and fast-lube chains. I keep those SKUs ready. But many new European and Asian models use cartridges. So I help you blend. You can carry both, with one supplier, one invoice, one support team. You get consistent test data and packaging. You lower noise in your warehouse.

Conclusion

I do not chase a trend. I follow what the engine needs and what your business needs. Spin-on filters7 fit speed and simplicity. Cartridge filters fit waste goals and cost control. At Runex Auto, I build both to OE performance. I test, I certify, and I deliver on time. I help you stock well for peak season. I share data and simple guides. You get fewer comebacks and better margins.

-

Explore the benefits of spin-on filters, including ease of use and efficiency, to make informed decisions for your vehicle. ↩ ↩ ↩ ↩

-

Learn about the advantages of cartridge filters, such as reduced waste and visibility of debris, to enhance your maintenance strategy. ↩ ↩ ↩ ↩

-

Understand the waste disposal implications of each filter type to optimize your environmental impact and cost. ↩ ↩ ↩ ↩

-

Understanding filtration performance is crucial for selecting the right oil filter, ensuring optimal engine protection and efficiency. ↩ ↩

-

Exploring flow and protection can help you grasp how oil filters maintain engine health under various conditions. ↩

-

Learning about build and seal materials can guide you in choosing durable and reliable oil filters for your vehicle. ↩

-

Find the best auto oil filter from Runex Auto. ↩