When someone tries to cut costs or simplify sourcing by choosing a smaller oil filter, it may look harmless at first. But it can quickly spiral into serious mechanical issues and customer complaints.

Using a smaller oil filter may cause early clogging, oil starvation, pressure drops, and even irreversible engine damage. Always stick with the right size.

When a client once used a smaller oil filter to save money, the engine suffered oil starvation. It wasn’t long before he faced expensive engine wear. Since then, he insists on OE-sized Runex filters only. Mistakes teach fast—especially when they cost thousands.

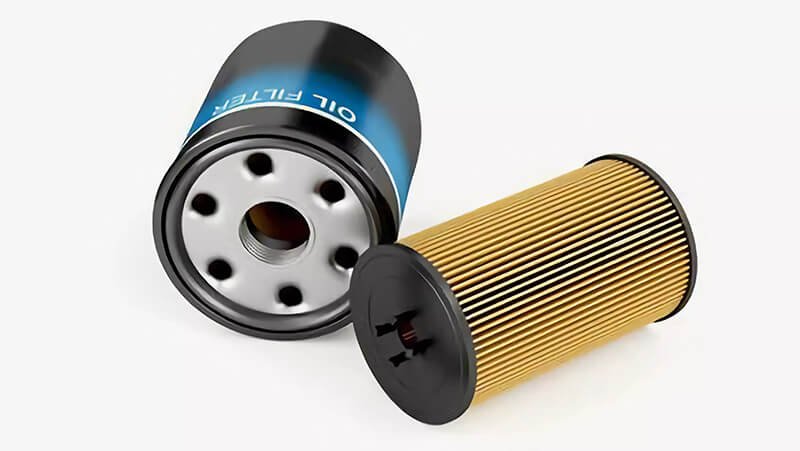

Is it okay to use a smaller oil filter?

Sometimes customers assume a slightly smaller filter won’t matter much. After all, if it threads on, it must work, right? Not quite. That’s a dangerous assumption in real-world automotive maintenance.

A smaller oil filter may not hold enough oil or withstand the same pressure. It can clog early, reduce oil flow, or even rupture—leading to major engine damage.

Why Size Matters

Even if a smaller filter looks like it fits, several hidden risks follow:

- Reduced Filtration Capacity1: Smaller filters have less media. That means less debris captured and faster clogging.

- Pressure Problems: With less internal space, oil flow can be restricted. The pressure might spike or drop depending on engine conditions.

- Bypass Valve Mismatch2: Filters contain a bypass valve to allow oil to flow when clogged. If it opens too early or too late, it affects lubrication.

- Thermal Stress3: Smaller housings handle heat differently. Some can deform under load.

| Specification | OE-Sized Runex Filter | Smaller Generic Filter |

|---|---|---|

| Filtration Area | High | Limited |

| Burst Pressure | Up to 250 psi | Often below 200 psi |

| Flow Rate | Stable, high-capacity | May bottleneck flow |

| Bypass Valve Tuning | Engine-matched | Often generic |

We engineered Runex Auto filters with maximum debris capacity and burst resistance. Our designs meet OE specs for each vehicle, ensuring engine safety and long-term reliability. Cutting corners here is like skipping brake checks—it costs more in the long run.

What happens if you use a wrong size oil filter?

It may screw on perfectly. But inside the engine, things can go horribly wrong without warning. Filters are about more than just thread size.

Using the wrong size oil filter can cause leaks, pressure issues, improper filtration, or bypass valve misfires—risking engine life and warranty coverage.

Hidden Dangers of Mismatch

Here’s a true story. A distributor once called me, panicked. His client used a smaller filter to save space in a tight compartment. But once the engine warmed up, the filter ruptured. Oil flooded out. The engine seized. That $3 mistake became a $3000 repair.

There are several failure points when a filter doesn't match OE specs:

1. Seal Compatibility

The gasket ring may not seat properly, causing slow leaks or sudden blowouts.

2. Thread Engagement

Thread pitch or depth might differ slightly, causing unstable fitting that loosens over time.

3. Internal Valve Timing

Each engine has a pressure spec. A mismatched bypass valve4 can lead to:

- Too early opening = unfiltered oil.

- Too late opening = oil starvation5.

| Filter Mismatch Factor6 | Possible Consequence |

|---|---|

| Wrong gasket size | Leakage |

| Incompatible threads | Loosening |

| Incorrect height | Mounting issues |

| Weak canister wall | Burst under pressure |

At Runex Auto, every oil filter is designed and tested for exact match. We don't sell "one-size-fits-all" because engines don’t work that way. Our clients trust us because our filters always fit—and perform.

Can I use any oil filter that fits my car?

It’s tempting to think "if it fits, it works." Especially for procurement managers trying to optimize costs. But filters are more than fit—they must function at spec under stress.

No, you can't just use any filter that screws on. The right filter must meet flow rate, pressure tolerance, and filtration standards specific to your engine.

Fit ≠ Function

Some aftermarket filters advertise "universal fit7." That’s a red flag. An oil filter must match:

- Thread and Gasket Size

- Bypass Valve Calibration

- Burst Pressure Tolerance

- Filtration Efficiency and Capacity8

Procurement leaders like Joe Rich at Carlson Auto understand this well. It’s not just about avoiding failures—it’s about protecting a brand, reputation, and customer trust.

OE Spec Isn’t Optional

Runex Auto oil filters are manufactured to exact tolerances with:

- Premium filter media

- Double-layer steel casing

- Pressure-tested burst thresholds

- Vehicle-specific bypass valves

Any filter that lacks these can put engine systems at risk. Your filter doesn’t just keep oil clean—it keeps the whole engine alive.

Is it better to have a larger oil filter?

Some believe going slightly bigger could help—more filter media, more oil, better performance. It seems logical, but it’s not always the case.

Using a larger oil filter may sound safer, but if it's not designed for your engine, it can still cause sealing problems, clearance issues, or pressure imbalances.

When Bigger Isn’t Better

There are cases where high-performance engines use extended filters. But even then, the filter must be engine-approved9. Larger filters can:

- Hit engine components or undercarriage

- Have mismatched bypass valves

- Take longer to pressurize after start-up

| Filter Size Change | Potential Risk |

|---|---|

| Slightly Taller | Gasket misalignment |

| Larger Diameter | Clearance conflict |

| Higher Capacity | Cold start lag |

If you're considering size changes for performance upgrades10, consult your engine specs first. Our Runex engineering team always advises matching OE dimensions11 unless an upgrade is tested and validated.

Conclusion

Oil filters12 may be small, but the wrong choice can cost big. Whether it's using a smaller filter that clogs early, or a wrong-sized filter that bursts under pressure, the risks far outweigh the savings. As a trusted supplier, Runex Auto designs filters that meet OE specs exactly—because our clients can’t afford mistakes. If you're a procurement leader managing hundreds of orders, stay safe, stay specific, and choose filters built for the job.

-

Understanding reduced filtration capacity can help you choose the right oil filter for your engine's health and performance. ↩

-

Exploring this topic can provide insights into maintaining optimal engine lubrication and preventing damage. ↩

-

Learning about thermal stress can help you select filters that withstand high temperatures, ensuring engine longevity. ↩

-

Understanding the function of a bypass valve can help you appreciate its importance in maintaining engine health and performance. ↩

-

Learning about oil starvation can help you avoid serious engine damage and ensure your vehicle runs smoothly. ↩

-

Exploring filter mismatch factors can provide insights into maintaining optimal engine performance and avoiding costly repairs. ↩

-

Understanding the risks associated with universal fit oil filters can help you make informed decisions for your vehicle's maintenance. ↩

-

Learning about filtration efficiency and capacity can help you choose the right oil filter for optimal engine health. ↩

-

Understanding 'engine-approved' is crucial for ensuring compatibility and performance in your vehicle's filtration system. ↩

-

Exploring performance upgrades can help you enhance your vehicle's efficiency and power while maintaining safety and reliability. ↩

-

Learning about OE dimensions ensures that any modifications you make to your vehicle are safe and effective, preserving its integrity. ↩

-

Knowing about OEM Oil Filter from Runex Auto, clicking this link to get your best products for your Business. ↩