I see many buyers worry about pad changes. The noise, the shake, the cost. The risk feels high. I know that pain. I help distributors daily. I keep it simple. I use clear checks. I share real fixes that work.

Yes, you can replace brake pads without turning rotors if the rotors meet thickness, runout, and surface tests. If rotors are warped, worn, or glazed, you should resurface or replace them. This keeps braking strong and keeps wear even.

I work with many partners who buy brake pads at scale. I listen to their drivers. I test batches. I track returns. I have seen what works in the field. I will explain the checks, the math, and the steps I use. I will keep it clear and useful.

Do I need to change my rotors when I change my brake pads?

Many teams rush to change rotors. The budget breaks. The returns still come. I do not like guesswork. I use simple tests, and I use clean data. I show my partners when to keep rotors and when to swap them.

You do not always need new rotors with new pads. Keep rotors if thickness is above minimum, runout is within spec, and the surface is even. Replace or resurface rotors if they are warped, cracked, heat-spotted, or below thickness.

What I check first

I measure rotor thickness1 with a micrometer. I compare it to the minimum stamped on the hat. I measure at several points. I look for more than 0.02 mm variation across the face. If I see heavy variation, I plan to machine or replace. I check runout with a dial indicator on the hub. I keep it at or below 0.05 mm for most passenger cars. If the hub has rust, I clean it. If the flange is bent, I replace it. I also scan for heat spots, radial cracks, and blue marks. These signs point to heat stress. They cause noise and shake with any pad, even a high grade one.

How pad compound changes the call

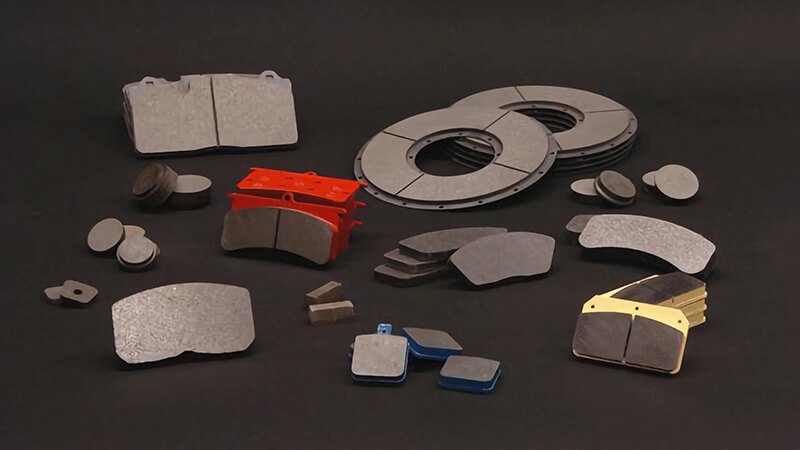

I design Runex Auto brake pads2 to seat fast and wear even on good rotors. We use stable friction materials. We use low-metallic and ceramic blends. We keep compressibility within tight windows. The pad face conforms and beds in well if the rotor face is clean and flat. If a rotor is glazed, a light non-directional finish helps. Often I use a 120 grit disc to break the glaze. Then I do a short bed-in drive.

When I say keep, machine, or replace

- I keep the rotor if thickness is above minimum by a safe margin, the face is smooth, and runout is in spec.

- I machine the rotor if thickness allows and if runout is marginal. I cut lightly and add a non-directional finish3.

- I replace the rotor if thickness drops near the limit, if cracks show, or if hard spots appear after a cut.

Field story from the UK

A distributor in the UK had complaints about quick pad wear. I reviewed returns. I asked for rotor data. The rotors were warped. The pads were fine. We switched to Runex Auto ceramic pads4 and resurfaced the rotors. The noise stopped. The wear rate dropped. The seller saw fewer returns and better reviews. This case reminds me that pads cannot correct rotor shape.

Quick reference table

| Check item | Keep rotor | Resurface rotor | Replace rotor |

|---|---|---|---|

| Thickness vs min | > 1.0 mm over | > 0.5 mm over | ≤ min or near min |

| Runout | ≤ 0.05 mm | 0.05–0.10 mm | > 0.10 mm |

| Surface | Smooth, no glaze | Light glaze or micro-grooves | Cracks, hot spots, deep grooves |

| Noise/Shake history | None | Intermittent | Recurring after service |

What is the average lifespan of brake pads?

Buyers ask me for a number. They want a safe stock plan. I get it. I use test data and fleet logs. I also know that driving habits change everything. So I give a range, and I show the key drivers.

Average brake pad life ranges from 25,000 to 70,000 miles. City stop-and-go reduces life. Highway miles extend it. Pad compound, rotor health, vehicle load, and climate also change wear. Runex Auto pads hold stable friction and resist fade, so they last longer in mixed use.

How I set the range

I watch pad life across fleets and consumer sets. I split routes into city, mixed, and highway. I track pad thickness5 at service. I compare friction materials6. I also monitor complaint rates for noise and dust. Over time, I see clear patterns. City routes with heavy stops wear pads fast. Highways with gentle stops keep pads healthy. Hills and loads add stress. Cold starts increase first-bite events, which add wear.

Why Runex Auto pads last well

We build our pads with strong binder systems. We use selected fibers for heat control. We add friction modifiers that keep the coefficient stable. This stops spike wear in high heat. Our backing plates use proper thickness steel. Our shims use multi-layer steel and rubber. This keeps vibration low. Less vibration means less micro-chipping at the pad edge. Our compounds hold shape under pressure. That keeps the contact patch even on the rotor. Even contact slows wear.

Testing that backs the numbers

I run SAE J2522 dynamometer tests7. I watch the friction curve at low and high speeds. I test fade and recovery. I also test compressibility and shear strength. I compare against OE baselines. In fleet pilots, our ceramic pads often reach 40,000 to 55,000 miles in mixed use on compact sedans. On light SUVs, I see 30,000 to 50,000 miles. Aggressive city vans can drop to 20,000 to 35,000 miles. With smooth drivers and healthy rotors, I see outliers above 70,000 miles.

What makes life shorter

- Hard braking habits that keep pads hot

- Warped or rough rotors that cut the pad face

- Cheap shims that allow squeal and edge wear

- Heavy loads and towing on hot days

- Dusty roads that grind the pad surface

What saves pad life

- Smooth decel with longer gaps

- Good rotors with a clean, even face

- Quality pad compounds with stable friction

- Strong adhesive bonds and proper bake cycles

- Correct bed-in after installation8

Simple life plan table

| Use case | Typical life (miles) | Notes |

|---|---|---|

| Urban delivery | 20,000–35,000 | Many stops, high heat |

| Mixed commute | 30,000–55,000 | Balanced profile |

| Highway heavy | 45,000–70,000+ | Gentle stops, steady speeds |

| Mountain/towing | 15,000–30,000 | High energy per stop |

What happens if you replace brake pads without turning the rotors?

I often see pad-only jobs done in a rush. The driver leaves. The shake comes back. The noise gets worse. The blame hits the pad. I know this pattern. I fix it with three basic checks before I fit new pads.

If you replace pads on bad rotors, you get uneven wear, noise, vibration, and longer stop distances. If rotors are straight, smooth, and thick enough, pad-only service works. Runex Auto pads bed quickly on clean, healthy rotors and deliver stable stops.

The risks in simple terms

Rotors that are warped will push the pads in and out. This makes the caliper pistons move back and forth. The pedal may pulse. The wheel may shake. The pad material may transfer in patches. This causes hot spots and glazing. Rotors that are rough will act like a file. They will cut the pad surface. The wear rate rises. The noise grows. Rotors that are too thin will heat faster. Heat fade will start earlier. Stopping distance will rise.

How Runex Auto pads handle marginal rotors

Our pad formula handles light surface issues. The compound seats fast. It can smooth light glaze. The shims reduce micro-vibration. The slots and chamfers control edge lift and noise. This helps during early miles. Still, the pad cannot fix heavy runout or deep grooves. If the rotor face is not right, I tell partners to resurface or replace. This is honest and it saves money later.

The UK case in practice

I worked with a UK distributor who had many returns for quick wear. The investigation showed warped rotors9. Many shops had done pad-only jobs10. We changed the process. We added a rotor check11 to every work order. We paired Runex Auto pads12 with resurfaced rotors or new rotors when needed. Complaints dropped fast. Drivers felt a calm pedal and smooth stops. Sales teams felt less pressure. This was a simple process change, not a marketing trick.

Key checks and limits

- Minimum thickness: keep safe margin above the spec

- Runout: target 0.05 mm or less at the rotor face

- Surface: remove glaze; avoid hard spots and cracks

- Hub face: clean rust; seat rotor flat; torque lugs in cross pattern

- Bed-in: do 8–10 moderate stops from 60 to 20 km/h; let cool between

Results you should expect

If you skip rotor work on bad rotors, you will likely see:

- Squeal or growl, often after a few days

- Pedal pulsation at high speed

- Steering shake under light braking

- Uneven pad imprint on rotor

- Short pad life and customer returns

If rotors pass the tests, and you use our pads, you should see:

- Quiet operation due to stable shims

- Even wear from controlled compressibility

- Strong bite with smooth pedal feel

- Predictable life that matches your stock plans

Decision table for pad-only jobs

| Rotor condition | Pad-only job | Action |

|---|---|---|

| Straight, smooth, thick | OK | Install pads, bed-in |

| Slight glaze, good thickness | OK with prep | Scuff rotor, then install |

| Moderate runout | Not OK | Resurface if thickness allows |

| Below min thickness | Not OK | Replace rotor |

| Hot spots or cracks | Not OK | Replace rotor |

How do I extend my brake pad life?

I treat pad life like a system. I look at drivers, rotors, calipers, and parts quality. I do not rely on luck. I use small steps that add up. I build a plan that a busy shop can follow every day.

You extend pad life by keeping rotors within spec, bedding pads right, using stable compounds, and training drivers to brake smoothly. You also prevent drag with clean slides and fresh hardware. Runex Auto pads and shims help by keeping friction stable and noise low.

Setup steps that make the biggest difference

- Clean the hub. Rust lifts the rotor. This adds runout and vibration.

- Measure rotor thickness and runout. Do not guess. Log the values.

- Replace hardware. Old clips and pins cause drag and uneven wear.

- Lubricate slides with high-temp grease. Keep boots intact.

- Torque wheels in a cross pattern. Uneven torque distorts rotors.

These steps take minutes. They prevent weeks of noise calls.

Bed-in that teaches the pad and rotor to work together

I run a simple bed-in13 after each install. I do 8 to 10 moderate stops from 60 to 20 km/h. I leave space and time between stops so parts cool. I avoid hard stops in the first 300 km. This builds a thin, even transfer layer. The layer reduces wear and noise. It also improves bite. Runex Auto pads14 form a stable transfer layer fast due to our resin system and modifiers.

Driver habits that save money

I teach drivers to look far ahead. I ask them to coast before braking. I ask them to keep gaps and avoid tailgating. I ask them to avoid riding the brake on long hills. I ask them to plan exits early. These habits keep pad temperatures low. This slows wear. This also keeps rotors straight.

Choosing the right Runex Auto compound

We offer ceramic pads for clean, quiet performance in daily use. We offer low-metallic pads for strong bite and heat control in heavier use. I match the compound to the route. I match it to the vehicle weight and wheel size. A good match increases life and safety.

Maintenance calendar I share with fleets

- Every 10,000 km: inspect pad thickness, check hardware, listen for noise

- Every 20,000 km: measure rotor runout and thickness

- Each tire rotation: clean slides, check boots, torque lugs

- At pad change: replace hardware, clean hub, bed-in properly

Tools and simple metrics

A micrometer and a dial indicator are cheap. They save more than they cost. A log sheet helps techs stay honest. I ask for three numbers per corner: pad thickness, rotor thickness, and runout. I check deltas over time. I react early.

Quick action table

| Action | Time cost | Benefit |

|---|---|---|

| Clean hub face | 5–8 min | Lower runout and vibration |

| Replace hardware | 3–5 min | Even wear, less drag |

| Slide lube | 2–3 min | Prevents sticking caliper |

| Proper torque | 1–2 min | Avoids rotor distortion |

| Bed-in drive | 10–15 min | Stable transfer layer, less noise |

Conclusion

I keep my advice simple. Pads15 can live long if rotors are healthy and drivers brake with care. You can do pad-only jobs when the rotors pass basic checks. When in doubt, resurface or replace. Runex Auto pads add stability, quiet, and even wear that you can trust.

-

Understanding rotor thickness is crucial for ensuring optimal brake performance and safety. ↩

-

Explore the advantages of Runex Auto brake pads for improved braking efficiency and reduced wear. ↩

-

Learn how a non-directional finish can enhance rotor performance and prolong brake life. ↩

-

Discover why ceramic brake pads are favored for their durability and performance in various conditions. ↩

-

Discover the importance of pad thickness in brake performance and how it influences safety and wear. ↩

-

Explore this link to understand how different friction materials impact brake performance and longevity. ↩

-

Learn about SAE J2522 tests to see how they ensure brake pad quality and performance under various conditions. ↩

-

Understanding the bed-in process can significantly enhance brake performance and extend pad life. ↩

-

Understanding the impact of warped rotors can help you maintain vehicle safety and performance. ↩

-

Discover the potential pitfalls of pad-only jobs to ensure effective brake maintenance. ↩

-

Learn why incorporating a rotor check can prevent costly repairs and improve vehicle safety. ↩

-

Explore how Runex Auto pads can enhance your braking system and reduce wear on rotors. ↩

-

Understanding the bed-in process is crucial for optimal brake performance and longevity. ↩

-

Explore the advantages of Runex Auto pads for improved braking efficiency and reduced noise. ↩

-

Find the best auto brake pads from Runex Auto. ↩