Finding the right oil filter manufacturer can feel overwhelming. The options are endless, but selecting the wrong supplier can lead to subpar products and lost business opportunities.

Choosing a reliable oil filter manufacturer ensures high-quality products, dependable supply chains, and improved customer satisfaction. It's crucial to balance cost, quality, and support.

Understanding the key factors in selecting an oil filter manufacturer will help you make informed decisions that benefit your business.

How to select an oil filter?

Selecting an oil filter requires understanding your specific needs and the manufacturer's capabilities. It's not a one-size-fits-all solution.

To select the right oil filter, consider the type of vehicles, engine requirements, and filtration needs. Choose a supplier who can meet these specifications consistently.

Dive Deeper: Essential Steps in Selection

When selecting an oil filter, you need to address the technical and practical aspects that define performance and reliability.

-

Understand Vehicle Requirements:

- Different engines demand specific filtration levels. For instance, high-performance engines may require filters with synthetic media for better contamination control synthetic media for oil filters1.

- Match the oil filter type to the oil viscosity recommended by the vehicle manufacturer.

-

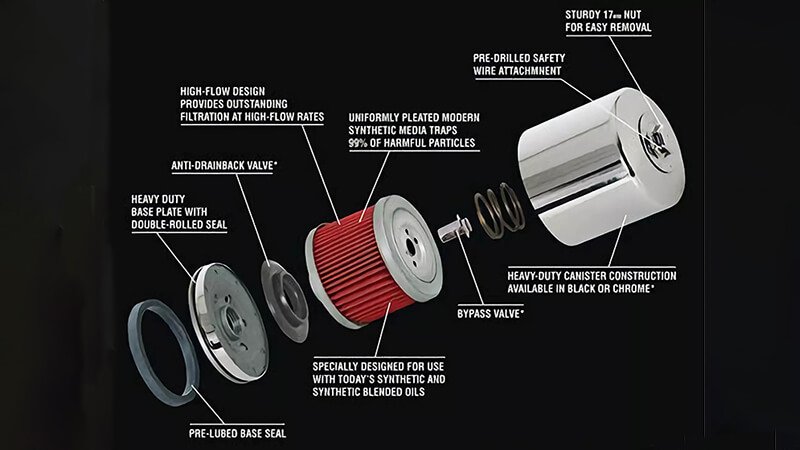

Evaluate Filter Specifications:

- Look for technical details such as filtration efficiency (percentage of contaminants removed) and dirt-holding capacity oil filter filtration efficiency explained2.

- Consider filters with bypass valves for added engine protection during high-pressure situations.

-

Assess Manufacturer Support:

- A good supplier should offer clear technical documentation and test reports.

- They should also provide support in understanding filter compatibility with your product line filter compatibility guidelines3.

-

Scalability and Reliability:

- Can the supplier scale production to meet your growing demands?

- Evaluate their history of timely deliveries and ability to handle supply chain disruptions.

By carefully analyzing these factors, you ensure that your oil filter selection aligns perfectly with the requirements of your customers and the vehicles they use.

What is the best brand for oil filters?

The "best" brand varies depending on your market and vehicle types. Leading brands often combine quality and innovation.

A great oil filter brand should offer reliable performance, consistent quality, and compatibility with your market's vehicles choosing a reliable oil filter brand4. Research their reputation and reviews.

Dive Deeper: Traits of Leading Brands

When assessing oil filter brands, it's critical to focus on what sets them apart:

-

Innovation and R\&D:

- Leading brands invest heavily in research, resulting in advanced filtration technologies advanced filtration technologies in oil filters5. For example, synthetic fiber filters provide better performance in modern engines.

-

Customer Support and Education:

- The best brands offer training programs and clear guides to help distributors and end-users understand their products better.

- They maintain robust after-sales service for addressing warranty issues and product queries.

-

Global Reach and Adaptability:

- Brands with a strong international presence are better equipped to meet diverse market needs. Their wide distribution networks minimize stock issues and delivery delays global oil filter brands and distribution6.

-

Performance in Real-world Applications:

- Evaluate how their products perform in rigorous conditions, such as extreme temperatures or high-pressure systems. This ensures reliability for both everyday drivers and heavy-duty users.

By choosing a top-performing brand, you not only secure better products but also enhance your reputation as a supplier offering proven quality.

Is there a difference between cheap and expensive oil filters?

The price of oil filters often reflects their quality, but it’s important to distinguish value from cost.

Cheap filters may compromise materials and filtration capacity, while expensive ones often ensure durability, efficiency, and better engine protection difference between cheap and expensive oil filters7.

Dive Deeper: Hidden Costs of Cheap Filters

While cheap filters may seem like a cost-effective choice initially, they often lead to significant issues down the line:

-

Subpar Materials:

- Low-cost filters typically use cellulose media, which degrades quickly cellulose vs synthetic oil filter media8. This can allow contaminants to pass through, damaging engine components over time.

-

Short Lifespan:

- Frequent replacements increase maintenance costs and inconvenience for customers. This can harm your reputation as a supplier.

-

Higher Risk of Failure:

- Inferior bypass valves and seals are more prone to leaks and malfunctions, risking engine failure during operation bypass valve quality in oil filters9.

-

Environmental Concerns:

- Low-quality materials often contribute to more waste, as they degrade faster and cannot be recycled effectively.

On the other hand, expensive filters use durable synthetic media, advanced sealing, and robust construction. These features reduce maintenance needs, enhance engine protection, and offer long-term value.

How do you check the quality of an oil filter?

Ensuring the quality of an oil filter requires a systematic approach. Physical inspection, certifications, and performance tests are essential.

Check quality by inspecting construction, verifying certifications, and testing filtration performance under real-world conditions how to verify oil filter quality10. Choose suppliers with strong quality assurance systems.

Dive Deeper: Comprehensive Quality Assurance Process

-

Physical Inspection:

- Examine the filter's structure. High-quality filters will have uniform pleats, strong housing materials, and flawless seals physical inspection guide for oil filters11.

-

Testing and Validation:

- Conduct laboratory tests to measure filtration efficiency and pressure resistance. Look for filters that remove at least 99% of particles larger than 20 microns filtration efficiency standards for oil filters12.

-

Industry Certifications:

- Reliable filters will comply with standards such as ISO 4548-12, which measures performance under real-world conditions. Always ask for supporting documentation.

-

Case Studies and Testimonials:

- Review data from existing customers and case studies. This can provide insights into the filter’s long-term performance in specific applications.

-

Supplier’s Manufacturing Practices:

- Evaluate their production facilities. A robust quality control system ensures that every filter meets consistent standards.

Quality assurance not only ensures product reliability but also safeguards your business against reputational risks arising from poor performance or product failures.

Conclusion

Choosing the right oil filter manufacturer can be a game-changer for your business. A thorough understanding of product specifications, brand reputation, and quality assurance ensures you partner with suppliers who align with your goals. By prioritizing quality, reliability, and customer support, you’ll secure a competitive edge, enhance your reputation, and build a foundation for long-term success.

-

Learn how synthetic media enhances oil filter performance in high-performance engines. ↩

-

Discover how filtration efficiency impacts oil filter effectiveness. ↩

-

Get insights into assessing oil filter compatibility for various vehicle engines. ↩

-

Learn criteria for selecting an oil filter brand based on quality and compatibility. ↩

-

Discover how innovative filtration technologies improve oil filter performance. ↩

-

Explore oil filter brands with proven international reach and reliability. ↩

-

Understand how pricing reflects the quality and performance of oil filters. ↩

-

Learn how material choice affects the durability and efficiency of oil filters. ↩

-

Discover how bypass valve quality impacts oil filter reliability and engine protection. ↩

-

Learn the steps to evaluate oil filter quality to ensure reliability and performance. ↩

-

Understand how to identify defects and quality issues during a physical inspection. ↩

-

Discover the industry benchmarks for effective filtration in oil filters. ↩