In 2025, the automotive industry will face new challenges and opportunities. Learn how to build a reliable, efficient supply chain that meets the demands of the future.

To create a reliable supply chain in the automotive industry in 2025, companies must integrate new technologies, streamline logistics, and focus on sustainability and risk management.

As the automotive landscape changes rapidly, staying ahead of supply chain challenges will be crucial for long-term success.

What will the automotive industry look like in 2025?

The automotive industry is undergoing a transformation, driven by electric vehicles1, AI 2, and evolving consumer preferences3.

In 2025, the automotive industry will be vastly different from today. Electric vehicles (EVs)4 will dominate the market, with global governments pushing for stricter environmental regulations and consumers demanding cleaner, more efficient vehicles. The push for autonomous vehicles5 and connected car technologies6 will further revolutionize the sector, creating a need for more sophisticated parts and components. This shift will require automakers and suppliers to rethink their entire supply chain, from sourcing raw materials to managing distribution channels.

Additionally, the focus on sustainability will continue to rise. Manufacturers will be pressured to not only provide high-quality products but to do so in a way that reduces environmental impact. This shift will push supply chains to become more transparent, traceable, and sustainable, with a greater emphasis on reducing waste, lowering carbon footprints, and adopting green technologies.

What is the supply chain in the automotive industry?

A supply chain in the automotive industry is a complex network that involves the procurement of raw materials, manufacturing of parts, and delivery of finished vehicles.

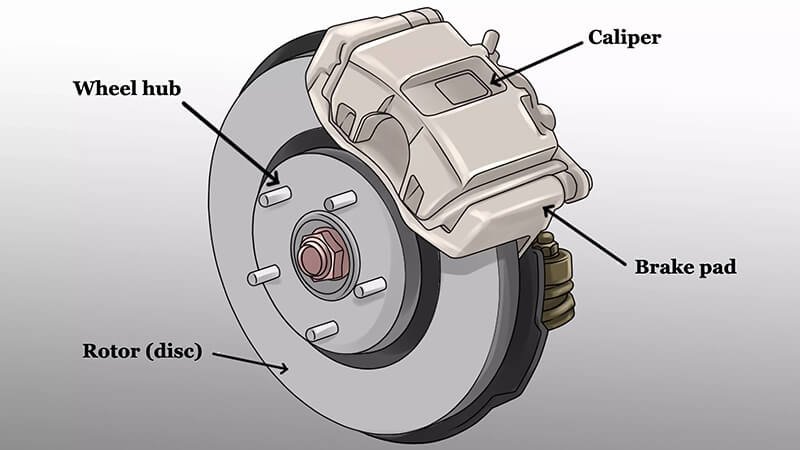

At its core, the automotive supply chain is a vast network of manufacturers7, suppliers8, logistics providers9, and distributors10 working together to create vehicles and auto parts. The chain begins with the sourcing of raw materials11, such as steel12, aluminum13, and plastic14. These materials are transformed into parts like engines, brake pads15, and air filters16, which are then assembled into vehicles. Finally, the vehicles are distributed17 globally to wholesalers, retailers, and consumers.

The complexity of the automotive supply chain lies in the numerous tiers of suppliers involved, each with its own challenges. For example, tier-1 suppliers18 directly work with automakers to provide key components, while tier-2 suppliers19 provide sub-components. As automakers push for more customized, high-tech solutions, the role of suppliers becomes increasingly critical in ensuring that the supply chain is efficient, cost-effective, and agile.

How do I make an effective supply chain?

An effective supply chain in the automotive industry requires strategic planning20, advanced technology21, and collaboration with trusted partners22.

To build an effective supply chain, it is essential to focus on three main pillars: visibility23, collaboration24, and agility25. First, achieving full visibility into the supply chain allows companies to track inventory, shipments, and supplier performance in real-time. This helps mitigate risks like delays, stockouts, or quality issues.

Second, strong collaboration with suppliers26 and logistics partners27 is vital. Building strong relationships with your suppliers and logistics providers ensures smooth communication and quicker response times. This becomes especially important in the automotive industry, where precision and on-time delivery are crucial.

Lastly, supply chains must be agile enough to quickly adapt to changes. This could involve pivoting production schedules, exploring alternative suppliers, or even implementing new technology to streamline processes. Companies should also embrace automation and artificial intelligence (AI) to predict demand more accurately and improve operational efficiency.

What is the future of supply chain automation?

Automation will play a pivotal role in reshaping the automotive supply chain, enhancing efficiency, and reducing costs.

As the automotive industry moves toward Industry 4.028, supply chain automation will be at the forefront of future success. In 2025, automation will encompass everything from robotic assembly lines to autonomous vehicles29 handling parts delivery. Technologies like AI30 and the Internet of Things (IoT)31 will be used to predict supply chain disruptions, optimize routing, and automate inventory management.\

Automated systems will also enable better demand forecasting, allowing manufacturers to produce parts in response to actual demand rather than estimates. This will reduce overproduction, minimize waste, and optimize inventory levels. The ability to track parts in real time will also enhance transparency, making it easier to manage quality control32 and ensure compliance with environmental regulations33.

How to improve supply chain strategy?

Improving your supply chain strategy is key to meeting evolving industry demands and ensuring long-term success.

Improving supply chain strategy involves several key steps. First, automakers and suppliers must invest in data analytics34 to gain insights into market trends and consumer behavior. This allows them to adjust production schedules and stock levels proactively.

Second, it is essential to optimize logistics35. This includes streamlining transportation routes, using predictive maintenance on transport vehicles, and leveraging digital platforms36 for real-time tracking. Working closely with third-party logistics providers37 can help ensure faster and more cost-effective delivery solutions.

Third, focusing on sustainability38 will be a major driver of future supply chain strategies. Companies will need to assess the environmental impact of every stage of the supply chain, from sourcing to delivery. This could include transitioning to renewable energy39 sources, adopting green packaging, and working with suppliers who adhere to sustainability practices.

What are the 7 key issues of supply chain management?

Leading paragraph: Navigating the complexities of automotive supply chains requires addressing several key issues that impact efficiency and profitability.

The seven key issues of supply chain management in the automotive industry are:

-

Supply Chain Visibility

- Real-time Insights: A lack of real-time visibility can lead to delays, mismanagement, and inefficiencies. Companies need systems that provide comprehensive tracking of materials and products throughout the supply chain.

-

Inventory Management

- Optimal Levels: Maintaining optimal inventory levels while avoiding overstocking or stockouts is a challenge. Effective inventory management strategies are essential to balance demand and supply.

-

Supplier Risk Management

- Diversification: Reliance on a few suppliers increases the risk of disruption due to geopolitical or economic changes. Companies should consider diversifying their supplier base to mitigate risks.

-

Transportation & Logistics

- Cost Efficiency: Efficient transportation is crucial to keep costs down and ensure timely deliveries. This involves optimizing routes, managing freight costs, and improving logistics processes.

-

Cost Control

- Balancing Act: Managing costs while maintaining quality and meeting customer demands is an ongoing challenge. Companies must implement cost-control measures without compromising product standards.

-

Technology Integration

- Seamless Systems: Ensuring that new technologies are seamlessly integrated into existing systems is critical for future success. This includes adopting advanced analytics, automation, and IoT solutions.

-

Sustainability

- Eco-friendly Practices: Companies should incorporate sustainable practices into their supply chain operations to reduce environmental impact and meet increasing consumer and regulatory demands for sustainability.

Conclusion

Leading paragraph: The future of the automotive industry lies in agile, tech-enabled, and sustainable supply chains.

As the automotive industry enters 2025, building a reliable supply chain requires adaptation to new technologies, shifting market demands, and evolving sustainability goals. By focusing on visibility, collaboration, automation, and strategic partnerships, companies can stay ahead of disruptions and drive long-term success. The key to thriving in this changing landscape lies in making data-driven decisions, optimizing every stage of the supply chain, and fostering a culture of continuous improvement.

By addressing the seven key challenges of supply chain management and aligning with future trends, auto parts manufacturers and suppliers can create resilient, efficient supply chains that support growth and meet the demands of a rapidly evolving market. Contact us to get your supplier chain for your business.

-

Learn about the rise of electric vehicles and their impact on the automotive market. ↩

-

Understand the role of AI in shaping the future of automobiles and driving innovation. ↩

-

Explore how changing consumer demands are shaping the future of car design and technology. ↩

-

Discover the future trends in EVs and their expected growth by 2025. ↩

-

Learn about autonomous driving technology and its future implications for the car industry. ↩

-

Find out how connected cars are transforming driving experiences and safety in 2025. ↩

-

Understand the key role manufacturers play in the automotive supply chain. ↩

-

Learn about the different types of suppliers and their importance in automotive production. ↩

-

Explore the critical role logistics providers play in the global automotive supply chain. ↩

-

Gain insights into the distribution process and key players in the automotive industry. ↩

-

Discover the basic raw materials essential for vehicle production. ↩

-

Find out how steel is used in automotive manufacturing and its impact on vehicle production. ↩

-

Learn how aluminum is used in the automotive industry for lightweight and performance benefits. ↩

-

Understand how plastic is used in vehicle production and its advantages. ↩

-

Learn about the importance of brake pads and how they contribute to vehicle safety. ↩

-

Discover the importance of air filters in maintaining vehicle performance. ↩

-

Understand how the automotive distribution process works across different regions. ↩

-

Learn about the direct suppliers to automakers and their role in production. ↩

-

Discover the role of tier-2 suppliers in providing sub-components to automakers. ↩

-

Learn why strategic planning is essential for building a successful and efficient supply chain. ↩

-

Discover how advanced technology transforms automotive supply chains for better efficiency. ↩

-

Understand how collaboration with trusted partners improves supply chain performance. ↩

-

Learn how visibility in the supply chain helps prevent risks and improve operations. ↩

-

Find out how effective collaboration with suppliers ensures timely delivery. ↩

-

Explore how supply chain agility helps companies adapt to changes and challenges. ↩

-

Understand the process of selecting suppliers and its importance in supply chain management. ↩

-

Learn about the vital role logistics partners play in ensuring a smooth supply chain. ↩

-

Learn how Industry 4.0 affects automation and the future of the automotive supply chain. ↩

-

Understand the role of autonomous vehicles in improving parts delivery efficiency. ↩

-

Discover how AI helps optimize supply chains and reduce disruptions. ↩

-

Explore the importance of IoT in managing logistics and inventory in real time. ↩

-

Learn how automated systems ensure better quality management and compliance. ↩

-

Find out how supply chain automation helps meet environmental standards. ↩

-

Discover how data analytics improves forecasting and decision-making in automotive supply chains. ↩

-

Learn key methods to improve supply chain logistics and reduce operational costs. ↩

-

Understand the role of digital tools in tracking, optimizing, and managing supply chains effectively. ↩

-

Get insights into how third-party logistics can enhance efficiency and reduce costs. ↩

-

Explore how sustainability practices improve supply chain efficiency and reduce environmental impact. ↩

-

Learn how renewable energy adoption can reduce supply chain costs and improve sustainability. ↩