Entering the automotive parts industry, especially as an oil filter distributor, can be lucrative. But navigating the process can feel overwhelming. Where should you begin, and what steps are essential for success?

To become an oil filter distributor, focus on market research, supplier relationships, and understanding customer needs. Building a reliable network and offering high-quality products will set you apart in this competitive market.

The journey to becoming an oil filter distributor requires careful planning and execution. Let’s explore the key aspects step by step to help you achieve success.

How to make money on oil changes?

Many businesses earn substantial revenue from oil changes, but profitability depends on strategic pricing and efficient operations. What’s the secret to maximizing earnings?

You can make money on oil changes by focusing on upselling services, sourcing quality parts at competitive prices, and maintaining customer trust. Efficient processes and value-added services can also boost your profitability.

Dive Deeper: Maximizing Profits from Oil Changes

To enhance profitability, consider these strategies:

1. Upselling Additional Services

Oil changes are a gateway to upselling related services. Offering add-ons like tire rotation, fluid top-ups, or air filter replacements can increase revenue1. Bundling these services into packages can also appeal to customers looking for comprehensive maintenance solutions.

2. Efficient Operations for Cost Savings

Minimizing time spent on oil changes without compromising quality can dramatically impact your bottom line2. Investing in staff training, standardized procedures, and reliable equipment reduces errors and improves throughput.

3. Strategic Sourcing

Partnering with reliable suppliers ensures you get oil filters and oil at competitive prices to maintain profitability3. Buying in bulk or forming partnerships can lower costs. A good supplier relationship is vital to sustaining your business.

4. Building Customer Trust and Retention

Customer loyalty programs, transparent pricing, and excellent service help build long-term trust4. Happy customers are more likely to return and recommend your services to others.

| Strategy | Key Action | Benefit |

|---|---|---|

| Upselling Services | Offer bundled packages | Increased revenue per visit |

| Operational Efficiency | Optimize workflows and training | Faster service delivery |

| Customer Loyalty | Introduce reward programs | Encourages repeat customers |

| Supplier Partnerships | Negotiate bulk discounts | Lower operational costs |

When these strategies are implemented effectively, they can turn oil changes from a low-margin service into a significant revenue driver for your business.

How do you change an oil and filter step by step?

Performing an oil change may seem straightforward, but attention to detail is crucial. What are the exact steps to ensure it’s done correctly?

To change an oil and filter, drain the old oil, replace the filter, and refill with the recommended oil type. Always double-check for leaks and proper oil levels before finishing.

Dive Deeper: Step-by-Step Process for Oil Changes

Here’s a detailed breakdown of how to perform an oil change:

1. Preparation and Safety

Before starting, ensure you have the correct tools and materials: wrenches, a drain pan, a funnel, gloves, and the recommended oil and filter to guarantee safety and efficiency5. Park the vehicle on a flat surface and let the engine cool to avoid burns.

2. Draining the Oil

Locate the oil drain plug underneath the car. Place the drain pan below it and carefully unscrew the plug. Let the oil drain completely, which can take several minutes depending on oil viscosity6.

3. Replacing the Oil Filter

Unscrew the old oil filter using an appropriate wrench. Before installing the new filter, apply a thin layer of oil to the gasket to ensure a proper seal and prevent leaks7. Hand-tighten the new filter securely.

4. Refilling with New Oil

Find the oil filler cap on top of the engine. Use a funnel to add the exact quantity of recommended oil to match vehicle specifications8. Refer to the vehicle’s manual for precise details.

5. Inspection and Testing

Start the engine and let it run for a minute. Turn it off, then check for leaks around the drain plug and filter to ensure everything is sealed correctly9. Recheck the oil level using the dipstick and top off if needed.

| Step | Tools Needed | Key Tips |

|---|---|---|

| Preparation | Gloves, funnel, oil | Work on a cool engine |

| Draining Old Oil | Drain pan, wrench | Avoid spills |

| Replacing the Filter | Wrench, new filter | Lubricate the gasket |

| Refilling with Oil | Funnel, oil bottle | Do not overfill |

| Inspect and Test | Dipstick | Check for leaks |

Each step requires precision to ensure engine safety and optimal performance.

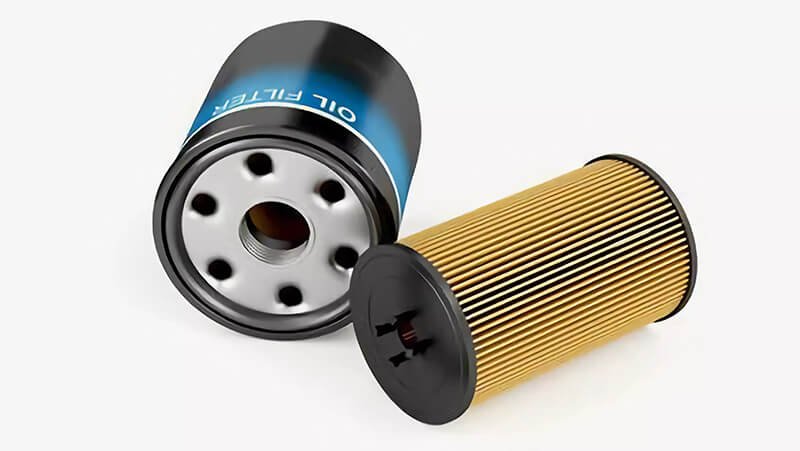

What are the three types of oil filters?

Choosing the right oil filter depends on the vehicle’s needs and engine type. But what are the main types, and how do they differ?

The three main types of oil filters are mechanical, cartridge and spin-on, and magnetic. Each type serves specific purposes and has unique benefits. Understanding these differences helps in making informed choices.

Dive Deeper: Comparing Oil Filter Types

1. Mechanical Oil Filters

These filters use multiple layers of porous material to trap contaminants in the oil to ensure engine cleanliness10. They are reliable and effective for general use but require regular replacement as they cannot be cleaned or reused.

2. Cartridge and Spin-On Filters

Cartridge filters are environmentally friendly as they allow for replacing just the filter element to reduce waste11. Spin-on filters are self-contained units, making installation quick and convenient for most vehicles12.

3. Magnetic Oil Filters

These filters incorporate magnets to capture metal particles from engine wear for heavy-duty applications13. They are ideal for engines that produce more metallic debris.

| Filter Type | Characteristics | Best For |

|---|---|---|

| Mechanical | Layered filter media | General-purpose use |

| Cartridge and Spin-on | Easy installation | Everyday vehicles |

| Magnetic | Attracts metal contaminants | Heavy-duty or industrial use |

Knowing the differences helps in choosing filters that meet your specific needs, whether it’s for everyday cars or specialized equipment.

What are the 5 steps to an oil change?

The process of changing oil involves multiple steps that must be executed precisely to avoid engine damage. What’s the simplest breakdown of this process?

The five steps to an oil change include preparation, draining old oil, replacing the filter, adding new oil, and inspecting the system. Following these ensures proper engine maintenance.

Dive Deeper: Simplified Oil Change Steps

Step 1: Preparation

Collect tools and confirm the type and quantity of oil required. Double-check that the car is on level ground to ensure accurate readings14.

Step 2: Draining Old Oil

Remove the drain plug and let the old oil flow out completely. Be cautious of hot oil to avoid burns15 if the engine was recently running.

Step 3: Replacing the Filter

Install a new oil filter after lubricating its gasket with fresh oil for a proper seal16. This prevents leaks and ensures reliable performance.

Step 4: Adding New Oil

Pour in the recommended amount of oil, taking care not to spill for accurate and efficient refilling17. Use a funnel to minimize mess.

Step 5: Testing and Final Inspection

Start the engine to circulate the new oil, then check the level and ensure there are no leaks for safety and performance18. Make adjustments as needed.

| Step | Action Taken | Common Mistakes to Avoid |

|---|---|---|

| Preparation | Confirm oil and tools are correct | Using the wrong oil type |

| Draining | Remove the drain plug carefully | Forgetting to replace plug |

| Replacing | Install the new filter properly | Over-tightening the filter |

| Adding | Pour in the exact quantity | Overfilling the oil |

| Testing | Inspect for leaks | Skipping post-check |

By following these steps meticulously, you can ensure efficient oil changes that protect the engine and enhance vehicle performance.

Conclusion

Becoming an oil filter distributor requires understanding profitability strategies, mastering essential oil change techniques, and knowing the types of oil filters. By focusing on these core areas, you can build a thriving business and become a trusted supplier in the automotive parts market. The journey may be challenging, but with careful planning and execution, success is within reach.

-

Discover why these add-ons are effective in boosting service revenue. ↩

-

Learn how to streamline oil change operations for higher profits. ↩

-

Get tips on finding reliable suppliers and reducing costs. ↩

-

Explore methods to retain customers and build trust for long-term success. ↩

-

Learn the tools and preparation steps for a safe and effective oil change. ↩

-

Understand how oil properties impact the drainage process. ↩

-

Discover how this step helps prevent leaks and ensures a tight seal. ↩

-

Find the right oil type and quantity for your vehicle. ↩

-

Learn how to verify a successful oil change and avoid issues. ↩

-

Learn how these filters work and why they are effective for general use. ↩

-

Understand how cartridge filters help reduce waste and support sustainability. ↩

-

Discover the convenience and compatibility of spin-on filters. ↩

-

Explore the benefits of magnetic filters for heavy-duty engine maintenance. ↩

-

Learn how uneven ground can affect oil level readings and engine maintenance. ↩

-

Discover tips to avoid burns and handle hot oil safely. ↩

-

Understand the role of lubricating the gasket in preventing leaks. ↩

-

Explore tips for clean and accurate oil refilling. ↩

-

Learn how to ensure your oil change is successful and leak-free. ↩