Brake shims are a critical yet often overlooked component in your vehicle’s braking system. Understanding their role can improve your car's performance and safety.

Brake shims help reduce noise, vibration, and premature wear, ensuring smoother and quieter braking. Here’s everything you need to know about them.

While brake shims may seem small, their impact on braking efficiency is significant. Let’s take a deeper look at why they’re so important.

Are brake shims necessary?

You may wonder if brake shims1 are really necessary for your vehicle's braking system. While they might seem like an optional add-on, they serve vital purposes.\

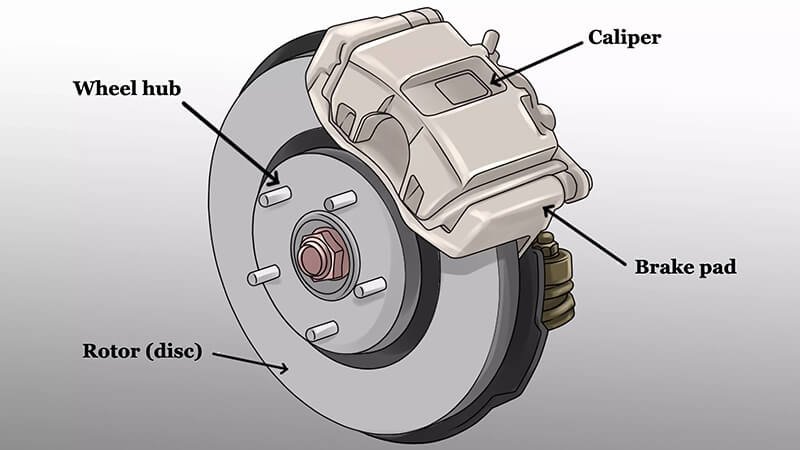

Brake shims2 are necessary to enhance braking performance and safety. They act as a buffer between the brake pads and the caliper, which helps to reduce vibrations and noise during braking. Without shims, the friction between the components could lead to unwanted sounds like squealing or scraping. They also improve the lifespan of both brake pads and rotors3 by minimizing uneven wear. In some cases, certain vehicles, especially luxury models, may require shims for their brake systems to maintain optimal performance.

Now that we’ve covered why brake shims are necessary, let’s explore the different types available.

Rubber Shims

- Material: Typically made from rubber or rubber-like materials.

- Function: Excellent at absorbing vibrations and reducing noise during braking. They provide a flexible barrier that dampens vibrations caused by friction between the brake pads and rotors.

- Durability: While they are effective for everyday driving conditions, rubber shims may not withstand extreme heat generated during high-speed driving or heavy braking.

Metal Shims

- Material: Often constructed from stainless steel or aluminum.

- Function: Effective at dissipating heat generated during braking, which helps prevent brake fade. They provide a stable support base for the brake pads, ensuring consistent contact with the rotor.

- Durability: More resistant to wear and tear compared to rubber shims, making them suitable for high-performance applications.

Rubber Steel Rubber (RSR) Shims

- Construction: These shims combine a rubber coating on a metal base.

- Benefits: They offer improved damping characteristics, reducing noise effectively while maintaining stability under high temperatures.

What are the different types of brake shims?

Brake shims are not one-size-fits-all. They come in various materials and designs, each tailored for specific braking needs.

The types of brake shims vary based on material and design. The most common materials include metal4, rubber5, and composite6.

-

Metal Brake Shims7: Typically made of stainless steel or copper, these provide durability and are effective at reducing vibration. They are ideal for high-performance vehicles where braking efficiency and longevity are essential.

**: Made from a high-quality rubber material, these shims help to absorb vibrations and reduce noise effectively. Rubber shims are popular in consumer vehicles due to their quieter operation and cost-effectiveness.

- Composite Brake Shims9: These are a combination of materials like rubber and metal, designed to offer a balance of noise reduction and heat dissipation. They are often used in performance-oriented vehicles where both durability and noise reduction are important.

Shims also come in various designs, including flat and wave-shaped options. The wave-shaped shims are better at distributing pressure more evenly, which helps with even brake pad wear.

While you now understand the different types of brake shims, another question arises—should brake pad shims be greased? Let’s find out.

Should Brake Pad Shims Be Greased?

The decision to grease brake pad shims is not straightforward and depends on several factors, including the type of shims used and the specific vehicle. Here are some key points to consider:

Benefits of Greasing Brake Pad Shims

- Reduced Noise: Greasing can help minimize brake noise caused by friction between the shim and other components. This is particularly important in high-performance or older vehicles where noise can be more pronounced.

- Smoother Operation: Lubrication allows for smoother movement of the brake pads against the caliper, which can enhance braking performance and reduce instances of jerky braking.

- Prevention of Uneven Wear: Proper lubrication can prevent shims from seizing, which may lead to uneven wear on brake pads. This is particularly relevant in climates with high moisture or corrosion potential.

When to Grease Brake Pad Shims

- Pre-Lubricated Shims: If your brake pad shims are pre-lubricated from the manufacturer, additional grease may not be necessary. Over-greasing can lead to dirt accumulation and potentially cause issues with braking performance.

- Vehicle-Specific Recommendations: Always follow the manufacturer's guidelines for your specific vehicle and brake system. In some cases, they may advise against additional lubrication.

Should brake pad shims be greased?

One common question is whether brake pad shims should be greased. The answer is nuanced and depends on the type of brake shim and the conditions of use.

Greasing brake pad shims can be beneficial, but it’s not always necessary. Some shims, especially rubber ones10, are designed to work without additional lubrication, while others may benefit from a thin layer of anti-squeal grease11. The grease helps to reduce friction and prevent noise by ensuring that the shim moves smoothly against the brake pad or caliper. However, over-applying grease can attract dust and dirt, which can affect braking performance, so it's important to apply only a small amount in the right areas.

Now that you know how to properly care for brake shims, let’s address the function of another important part—the brake rotor shim12.

What is a brake rotor shim used for?

The brake rotor shim13 is another key component in your braking system. You may wonder what role it plays compared to regular brake shims.

Brake rotor shims serve a different but equally important purpose. These shims are used between the brake rotor and the caliper bracket to help correct alignment and reduce vibrations during braking. This ensures that the brake pads contact the rotor evenly, preventing uneven wear and reducing noise. Rotor shims also help with heat dissipation14, which is critical in high-performance braking systems where excessive heat can cause brake fade15.

As we wrap up, let’s summarize the key takeaways and their importance for your vehicle.

Importance of Brake Rotor Shims

Functionality and Benefits

Brake rotor shims play a vital role in enhancing the overall performance of your braking system. Here are the key functions they serve:

-

Alignment Correction:

By providing a precise fit between the brake rotor and caliper bracket, shims help ensure that the brake pads make even contact with the rotor. This alignment is crucial for effective braking performance. -

Vibration Reduction:

The shims absorb vibrations that occur during the braking process, leading to a smoother and quieter operation. This not only enhances comfort but also prolongs the life of brake components. -

Even Wear Prevention:

Proper alignment and reduced vibrations contribute to even wear of the brake pads. This can save you money on premature replacements and improve safety by maintaining consistent braking power. -

Heat Dissipation:

In high-performance scenarios, managing heat is essential. Brake rotor shims assist in dissipating heat generated during braking, minimizing the risk of brake fade, which can significantly impair stopping power.

Conclusion

Brake shims, though small, are essential for the safety, efficiency, and longevity of your braking system. Understanding their function, types, and care can ensure your vehicle operates smoothly and quietly.

In conclusion, brake shims are necessary for reducing noise, improving braking performance, and prolonging the life of your braking components. By choosing the right type of shim and maintaining it properly, you can enhance the overall safety and comfort of your vehicle. Whether you’re replacing brake pads or performing routine maintenance, don’t overlook the importance of these small but mighty components.

Contact us to get your solutions and best parts for your business.

-

This link will provide an explanation about what brake shims are and their role in vehicle brake systems. ↩

-

Learn how brake shims help reduce vibrations, noise, and wear, improving overall braking efficiency. ↩

-

This link will explain the interaction between brake rotors, pads, and shims for better braking performance. ↩

-

This link will provide an overview of the materials commonly used in brake shims and their advantages. ↩

-

This link explains the benefits of rubber brake shims, including noise reduction and cost-effectiveness. ↩

-

This link will explain the characteristics of composite brake shims and their uses in high-performance vehicles. ↩

-

Learn how metal brake shims contribute to vibration reduction and durability in braking systems. ↩

-

This link will describe why rubber brake shims are ideal for consumer vehicles, focusing on noise reduction and comfort. ↩

-

Understand the benefits of composite brake shims, including a balance of noise reduction and heat dissipation. ↩

-

This link explains the characteristics of rubber brake shims and their advantages in reducing noise and vibration. ↩

-

Learn about the purpose of anti-squeal grease and how it helps reduce friction and noise. ↩

-

This link provides information on the function and importance of brake rotor shims in braking systems. ↩

-

This link explains the role and benefits of brake rotor shims in improving braking performance and alignment. ↩

-

Learn about the importance of heat dissipation in brake systems and its impact on performance and safety. ↩

-

This link provides an overview of brake fade, its causes, and how to prevent it in high-performance systems. ↩