Many buyers think bigger engines need bigger oil filters. It sounds logical, right? But real-world experience proves this idea is misleading. Choosing the wrong oil filter—no matter the size—can hurt your engine.

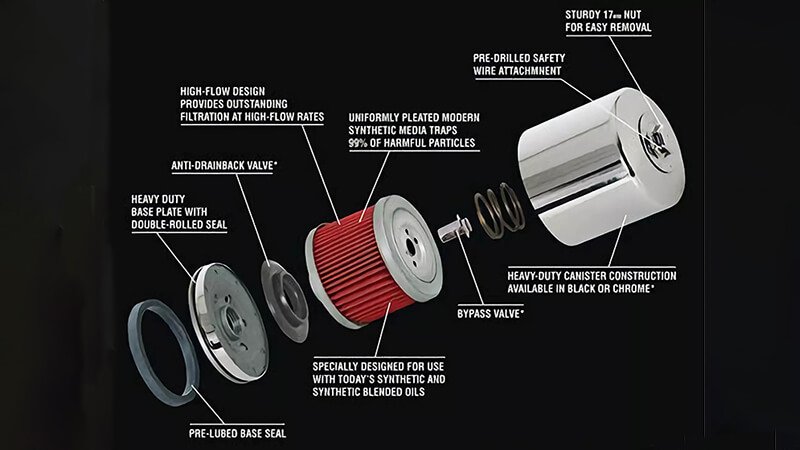

Engine size alone does not decide which oil filter you need. The key is matching the oil filter’s capacity, anti-drain-back valve, and bypass valve to your engine’s requirements.

When I started Runex Auto, I noticed how often clients picked filters based only on engine size. The result? Engine issues, oil pressure warnings, and even breakdowns. That’s why I always remind customers: specs matter more than size.

Does engine size matter for the oil filter?

Many people believe bigger engines need bigger oil filters. It feels logical because larger engines seem to demand more oil flow and filtration. But that’s not always true.

Engine size affects oil demands, but oil filter selection depends more on filter efficiency, pressure handling, and valve design. Using the right specs keeps engines safe, regardless of size.

Engine Size vs Oil Filter Specs: What Really Matters

When it comes to oil filters, thinking "bigger is better" often backfires. Here’s why:

| Factor | Impact on Oil Filter Choice |

|---|---|

| Engine Size | Affects oil flow needs, but not filter design alone |

| Filter Capacity1 | Must handle oil volume under high RPMs |

| Anti-Drain-Back Valve2 | Prevents oil drain-out at shutdown |

| Bypass Valve | Ensures oil flow if filter clogs |

| OEM Specifications3 | Ensure filter matches engine’s real requirements |

At Runex Auto, we design oil filters based on actual engine specs, not just engine size. For example, one of my UK clients ordered filters for delivery vans. They assumed bigger engines meant standard large filters. But those filters lacked proper anti-drain-back features. Engines ran rough, oil pressure alerts triggered. Once we supplied filters matching OEM pressure and valve specs, the engines ran smoothly.

Even smaller engines sometimes need high-efficiency filters. Modern engines run hotter, at higher RPMs. Using the wrong filter—even on a small engine—risks oil starvation or contamination.

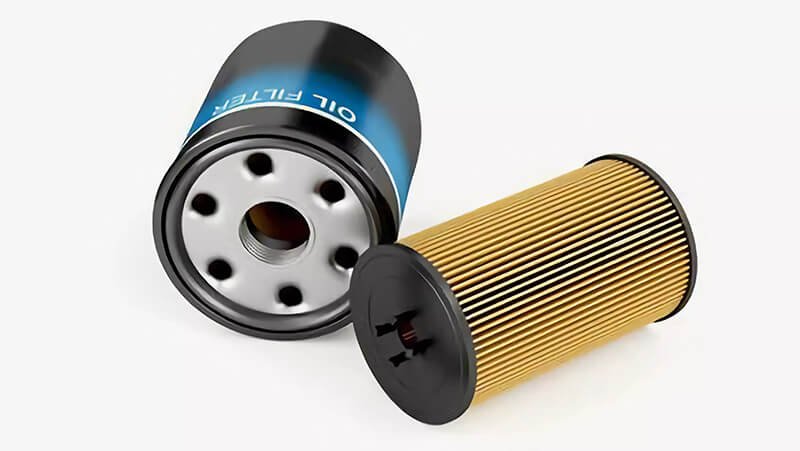

Can you put on any size oil filter?

It’s tempting to grab any oil filter that threads on and fits. I’ve seen buyers do this to save time or money. But this shortcut often damages engines long term.

You can physically fit many oil filters onto an engine, but only filters with the correct specs—capacity, valve system, pressure rating—keep your engine protected. Wrong-sized filters risk leaks, oil starvation, and failures.

Why “One Size Fits All” is Dangerous for Oil Filters

Oil filters may look similar, but inside, key differences matter:

| Component | Importance for Engine Safety |

|---|---|

| Filter Media Quality4 | Captures harmful particles, protects engine parts |

| Capacity Rating5 | Handles oil volume during peak engine demand |

| Valve System | Maintains oil pressure and prevents drain-back |

| Bypass Valve Setting6 | Allows emergency oil flow if filter clogs |

At Runex Auto, every oil filter undergoes strict quality control. We test filter media efficiency, valve response time, and bypass function. This ensures our filters meet or exceed OEM standards.

I remember another client—an aftermarket distributor in Europe—ordered “universal” filters to simplify stock. The filters fit physically, but lacked proper bypass valves. Engines experienced oil starvation at high speeds. We replaced them with Runex Auto filters, designed to meet each engine’s specs. Their return rates dropped, customer satisfaction improved.

So, just because a filter fits doesn’t mean it works properly.

Can I use the wrong size oil filter?

Yes, and I’ve seen the consequences firsthand. Wrong-sized oil filters seem harmless at first. But over time, they trigger oil leaks, poor filtration, or even engine damage.

Using the wrong oil filter—even if it threads on—risks oil starvation, low pressure alerts, engine wear, or total breakdowns. Filter size must match OEM specs for safe operation.

What Goes Wrong with Incorrect Oil Filter Sizes

Let me break it down with real examples:

| Wrong Filter Scenario | Common Engine Problem |

|---|---|

| Too Small Filter | Clogs faster, limits oil flow, causes pressure drops |

| Too Large Filter | Poor fit, oil leaks, pressure instability |

| Missing Anti-Drain-Back | Oil drains overnight, dry starts, engine wear7 |

| Incorrect Bypass Valve | Oil starvation during high RPMs or filter clogging |

At Runex Auto, I’ve worked with fleets and distributors who faced these issues. One customer used filters based on thread size alone. Engines suffered from startup ticking noises—a classic dry-start sign. We switched them to properly sized filters with anti-drain-back valves8. Engine noises vanished, performance improved.

Wrong filters don’t just affect oil flow. They impact emissions, fuel economy, and long-term engine life. Even if an engine runs with the wrong filter today, hidden damage builds over time.

How do I know what size oil filter I need?

Choosing the right oil filter starts with the correct information. Relying on engine size alone often leads to mistakes. You need the full specs.

Check your vehicle manual, use OEM part references, or work with trusted suppliers like Runex Auto to ensure your oil filter matches thread size, gasket placement, flow rate, valve specs, and capacity.

Steps to Find the Correct Oil Filter

Here’s my simple process for finding the right oil filter:

- Check OEM Part Numbers9: Vehicle manuals list approved filter options.

- Match Critical Dimensions:

- Thread size

- Gasket diameter

- Filter length (if space is limited)

- Review Filter Specs:

- Anti-drain-back valve (for engines needing oil retention)

- Bypass valve setting (avoids oil starvation under clog)

- Filter media efficiency10 (traps harmful particles)

- Consult Reliable Suppliers:

Runex Auto provides oil filters designed to meet or exceed OEM standards. We supply detailed specs for each filter, including pressure ratings and valve designs.

Many of my clients appreciate this detailed approach. One European distributor told me switching to our filters reduced engine complaints by 70%. Our filters fit properly, maintain oil flow, and protect engines—even under tough conditions.

Bonus Tip: Avoid “universal” filters without proper spec verification. Even a small mismatch can lead to expensive repairs.

Conclusion

In the oil filter world, size alone doesn’t guarantee safety. What counts is matching the filter’s technical specs to your engine. I’ve seen fleets run smoother, engines last longer, and customer satisfaction improve when the right oil filters11 are used. At Runex Auto, we help clients avoid costly mistakes by providing high-quality, spec-verified oil filters designed for real-world performance.

-

Explore the importance of filter capacity in handling oil volume, especially under high RPMs, to avoid engine issues. ↩

-

Learn how an anti-drain-back valve works to prevent oil drain-out, which is essential for maintaining engine health. ↩

-

Understanding OEM specifications is crucial for selecting the right oil filter, ensuring optimal engine performance and longevity. ↩

-

Understanding filter media quality is crucial for engine protection. Explore this link to learn how it impacts performance and longevity. ↩

-

Capacity rating is vital for handling oil volume. Discover how it influences engine efficiency and reliability by checking this resource. ↩

-

The bypass valve setting is essential for emergency oil flow. Learn more about its significance in maintaining engine health through this link. ↩

-

Discover the connection between oil filter size and engine wear to safeguard your vehicle's health and performance over time. ↩

-

Learn how anti-drain-back valves protect your engine from dry starts and enhance oil flow, ensuring better performance and longevity. ↩

-

Understanding OEM Part Numbers is crucial for selecting the right oil filter, ensuring compatibility and performance. ↩

-

Exploring filter media efficiency helps you understand how well an oil filter traps harmful particles, enhancing engine protection. ↩

-

Find the best OEM Auto Oil Filter from Runex Auto. ↩